Dec . 06, 2024 01:18 Back to list

Top Manufacturers of Pneumatic and Hydraulic Cylinders for Industrial Applications

The Significance of Pneumatic and Hydraulic Cylinder Manufacturers

In today's advanced industrial landscape, the demand for efficient and reliable machinery is higher than ever. At the heart of many systems are pneumatic and hydraulic cylinders, essential components that convert energy into mechanical force. Manufacturers specializing in these technologies play a crucial role in various sectors, including manufacturing, construction, aerospace, and automotive industries. This article explores the importance of pneumatic and hydraulic cylinder manufacturers, their production processes, applications, and technological innovations.

Understanding Pneumatic and Hydraulic Cylinders

Pneumatic cylinders utilize compressed air to produce motion, while hydraulic cylinders rely on pressurized fluid to achieve the same outcome. Both systems provide linear motion and can exert significant force, making them indispensable in many mechanical applications. Their uses range from simple actuation in assembly lines to complex movements in aerospace applications.

The Role of Manufacturers

Manufacturers of pneumatic and hydraulic cylinders are tasked with designing, producing, and testing these vital components to meet industry standards and customer requirements. They engage in extensive research and development to innovate and improve cylinder designs, ensuring enhanced performance, durability, and efficiency. Their expertise allows them to cater to a variety of needs, from standard cylinders to custom solutions tailored for specific applications.

Production Process

The production process for pneumatic and hydraulic cylinders is intricate, involving several stages to ensure quality and reliability. The first step typically includes material selection, where manufacturers choose high-grade materials such as aluminum, stainless steel, or composite materials that can withstand pressure and wear. After material selection, precision machining is conducted using advanced CNC (Computer Numerical Control) machines to fabricate components like rods, barrels, and end caps.

Once the components are machined, they undergo assembly. This process may involve fitting seals and o-rings that prevent leaks and ensure seamless operation. Following assembly, manufacturers conduct rigorous testing, including pressure tests and cycle testing, to verify that each cylinder operates under specified conditions without failure. Quality assurance at every stage is paramount to ensure that the final product can withstand the demands of its intended application.

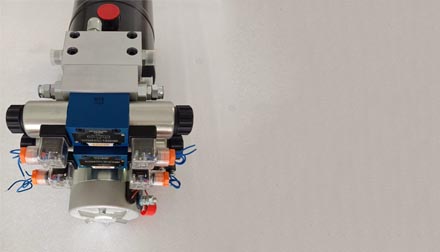

pneumatic hydraulic cylinder manufacturer

Applications Across Industries

Pneumatic and hydraulic cylinders find applications in a wide range of industries. In manufacturing, they power robotic arms and automated machinery, enhancing production efficiency. In the construction industry, hydraulic cylinders operate heavy machinery like excavators and cranes, allowing for precise movements and heavy lifting. The automotive sector employs these cylinders in both assembly lines and vehicle operation systems, such as brakes and steering mechanisms.

In aerospace, manufacturers utilize hydraulic cylinders in various control systems, ensuring the reliable operation of everything from landing gear to wing flaps. The recent trend towards automation and robotics has only intensified the demand for effective pneumatic and hydraulic solutions across these industries.

Technological Innovations

As industries evolve, so too do the technologies associated with pneumatic and hydraulic cylinders. Smart technology integration is a significant trend, with manufacturers increasingly focusing on incorporating sensors and IoT (Internet of Things) capabilities into their products. This allows for real-time monitoring and predictive maintenance, minimizing downtime and enhancing operational efficiency.

Moreover, there is a growing emphasis on sustainability in manufacturing processes. Many manufacturers are adopting eco-friendly practices, such as sourcing recyclable materials and implementing energy-efficient production techniques. This not only reduces their environmental footprint but also aligns with the global push towards greener manufacturing practices.

Conclusion

The role of pneumatic and hydraulic cylinder manufacturers is foundational in driving the efficiency and reliability of various industrial applications. Through advanced manufacturing processes, quality assurance, and a commitment to innovation, these manufacturers continue to be at the forefront of technological advancements. Their contributions not only enhance machinery performance across multiple sectors but also lead toward a more sustainable and automated future. As industries continue to evolve, the importance of these specialized manufacturers will undoubtedly grow, securing their place as key players in the industrial landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025