Nov . 26, 2024 00:38 Back to list

Hydraulic Cylinder Manufacturer Parts and Components Overview for Optimal Performance

Parts for Hydraulic Cylinder Manufacturers An In-Depth Overview

Hydraulic cylinders are essential components in a myriad of industrial applications, from construction equipment to manufacturing processes. Their effective performance relies largely on the quality and design of the parts used in their assembly. For manufacturers of hydraulic cylinders, the selection and procurement of parts are critical to ensure optimal functionality, durability, and safety. This article delves into the key components that make up hydraulic cylinders, the importance of quality manufacturing, and current trends in the industry.

Key Components of Hydraulic Cylinders

A hydraulic cylinder typically consists of several integral parts, each playing a specific role in its operation.

1. Cylinder Barrel The barrel is the main body of the hydraulic cylinder, typically made of high-strength steel to withstand internal pressure. It houses the piston and allows the hydraulic fluid to create pressure against the piston for efficient force generation.

2. Piston The piston is a crucial component that moves within the cylinder barrel. When hydraulic fluid is pumped into the cylinder, pressure is exerted on the piston, causing it to move. The design and material of the piston can significantly affect the cylinder's performance and efficiency.

3. Rod The rod extends from the piston and is the component that transfers the generated force to the application. It must be made of high-strength materials to handle tensile and compressive forces while resisting bending during operation.

4. Seals Sealing components are vital for maintaining pressure within the cylinder and preventing hydraulic fluid leakage. High-quality seals are essential for preventing contamination and ensuring longevity, as wear and tear can lead to cylinder failure.

5. End Caps These components close the ends of the hydraulic cylinder and provide attachment points for the rod and barrel. They are designed to withstand significant pressure and must be engineered to match the dimensions and characteristics of the cylinder.

6. Ports and Fittings Ports are the openings through which hydraulic fluid enters and exits the cylinder. The fittings connected to these ports allow for efficient fluid transfer and connection to the hydraulic system.

Importance of Quality Manufacturing

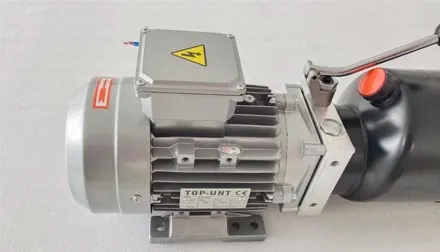

parts for hydraulic cylinder manufacturer

The performance and reliability of hydraulic cylinders heavily depend on the quality of their individual parts. Manufacturers must prioritize high-quality materials and precision engineering to ensure that their products can withstand harsh operational conditions.

This involves stringent quality control measures throughout the manufacturing process. From sourcing raw materials to final inspections, manufacturers must employ practices that uphold industry standards. Advanced technologies such as CNC machining, surface treatment, and rigorous testing methods can significantly enhance the performance of hydraulic cylinder parts.

Moreover, adherence to international standards, such as ISO certifications, can provide customers assurance of the quality and reliability of the products. Achieving and maintaining these standards can give manufacturers a competitive edge in the market.

Current Trends in the Industry

As technology evolves, so does the hydraulic cylinder manufacturing industry. Several current trends are shaping the future of hydraulic cylinders

- Smart Technology Integration The emergence of smart technology in hydraulic systems is allowing for enhanced monitoring and diagnostics. Sensors can be incorporated into hydraulic cylinders to track performance metrics, fluid viscosity, and temperature, enabling predictive maintenance and decreasing downtime.

- Sustainability Practices With increasing awareness of environmental issues, many manufacturers are leaning towards sustainable practices. This includes using eco-friendly materials, reducing waste, and ensuring that production processes are energy efficient.

- Customization There is a growing demand for customized hydraulic cylinders tailored to specific applications. Manufacturers are increasingly providing bespoke solutions, working closely with clients to design and manufacture cylinders that meet unique operational needs.

- Innovation in Materials Research into new materials, such as advanced composites and hybrid materials, is ongoing. These materials promise lighter weights and improved durability, which can potentially lead to enhanced efficiency and performance.

Conclusion

In conclusion, the components that make up hydraulic cylinders are critical to their effective operation and reliability. For manufacturers, focusing on high-quality parts, innovative manufacturing processes, and adaptation to industry trends is essential for success in a competitive market. As technology and customer demands continue to evolve, staying ahead in the hydraulic cylinder manufacturing industry requires a commitment to quality, innovation, and sustainability. By understanding and prioritizing these aspects, manufacturers can ensure they provide superior products that enhance the performance of hydraulic systems across various applications.

-

Pallet Truck Power Units: Smart Logistics Solutions

NewsAug.01,2025

-

1.5 Ton Lifting Cylinder - Hebei Shenghan | Heavy-Duty Hydraulic Solutions

NewsAug.01,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Heavy-Duty Lifting, Precision Engineering

NewsAug.01,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Lifting Solutions

NewsAug.01,2025

-

Double Acting Power Unit with GPT-4 Turbo | AI Hydraulics

NewsJul.31,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic|Heavy-Duty Lifting,Custom Hydraulic Solutions

NewsJul.30,2025