Dec . 06, 2024 17:58 Back to list

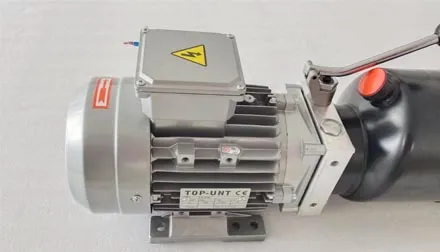

oil hydraulic cylinder product

Understanding Oil Hydraulic Cylinders An Overview

Oil hydraulic cylinders play a crucial role in various industrial applications, particularly in the fields of construction, manufacturing, and automotive industries. These devices convert hydraulic energy into mechanical energy, providing powerful linear motion to perform various tasks efficiently. In this article, we will explore the fundamental principles behind oil hydraulic cylinders, their components, applications, and advantages.

What is an Oil Hydraulic Cylinder?

An oil hydraulic cylinder is a mechanical actuator that uses pressurized hydraulic fluid to create motion. The basic mechanism consists of a cylinder barrel, piston, and rod. When hydraulic fluid is pumped into the cylinder, it exerts pressure on the piston, forcing it to move. This movement can then be harnessed to produce significant force, making hydraulic cylinders suitable for tasks that require high power in confined spaces.

Components of an Oil Hydraulic Cylinder

1. Cylinder Barrel The main body of the hydraulic cylinder houses the piston and provides a sealed environment for the hydraulic fluid. Typically made from high-strength steel or alloy, it is designed to withstand high pressure.

2. Piston Positioned inside the barrel, the piston separates the hydraulic fluid chambers. As fluid is introduced into one side of the piston, it moves, creating linear motion. Piston seals are critical to preventing fluid leakage and maintaining pressure.

3. Rod Connected to the piston, the rod extends out of the cylinder and is attached to the external machinery or systems that require motion. The rod must endure considerable stress and is often treated for durability.

4. End Caps These enclose the ends of the cylinder, ensuring that the hydraulic fluid remains contained and that the piston can operate without external interference.

How Oil Hydraulic Cylinders Work

oil hydraulic cylinder product

The operation of an oil hydraulic cylinder begins with the hydraulic pump delivering pressurized oil into the cylinder. Depending on the design of the cylinder, oil may be directed to either side of the piston to control the direction of movement. By managing the flow of hydraulic fluid, operators can achieve precise control over the speed and force applied by the cylinder.

Applications of Oil Hydraulic Cylinders

Oil hydraulic cylinders are utilized in various applications, including

- Construction Equipment Hydraulic cylinders are foundational in diggers, excavators, and loaders, applying substantial force to lift heavy materials. - Manufacturing In factories, hydraulic cylinders are used in assembly lines, presses, and robotic systems to facilitate automation. - Automobile Industry Hydraulic cylinders are crucial for lifting vehicles during maintenance, as well as in braking and steering systems. - Aerospace These cylinders are employed in aircraft for flight controls and landing gear mechanisms, requiring precision and reliability.

Advantages of Oil Hydraulic Cylinders

1. High Power-to-Weight Ratio Hydraulic cylinders can produce significant force relative to their size, making them ideal for applications where space is limited.

2. Ease of Control The ability to regulate the flow of hydraulic fluid allows for precise control over speed and force, providing operators with the ability to execute complex tasks.

3. Durability and Reliability Designed to withstand harsh conditions and high pressures, hydraulic cylinders have a long service life when maintained properly.

4. Versatility These cylinders can be adapted for various applications across multiple industries, making them a versatile solution for mechanical actuation needs.

Conclusion

Oil hydraulic cylinders are essential components in many modern industries, providing efficient and powerful linear motion for a wide range of applications. Understanding their design, function, and the benefits they offer can help industries maximize productivity and performance. As technology advances, hydraulic cylinder designs continue to improve, offering even greater efficiency and capabilities to meet the demands of evolving industrial challenges.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025