Nov . 18, 2024 10:27 Back to list

Top Manufacturers of Hydraulic Cylinders and Their Products

Exploring the World of Hydraulic Cylinder Companies

Hydraulic cylinders play a critical role in various industrial applications, serving as essential components in machines that require linear motion. These devices utilize hydraulic fluid pressure to create movement, making them invaluable in construction, manufacturing, and even automotive applications. The demand for high-quality hydraulic cylinders has led to the emergence of numerous companies specializing in their design and manufacture. In this article, we will explore the landscape of hydraulic cylinder companies, focusing on their innovations, market trends, and contributions to industrial efficiency.

Understanding Hydraulic Cylinders

Hydraulic cylinders consist of a cylindrical barrel, a piston, and two end caps. When hydraulic fluid is pumped into the cylinder, it creates pressure on the piston, resulting in linear movement. This simple yet effective mechanism allows for the conversion of hydraulic energy into mechanical work, making hydraulic cylinders ideal for tasks such as lifting heavy loads, pressing materials, and operating machinery.

The Leading Manufacturers

Among the prominent players in the hydraulic cylinder market are companies such as Parker Hannifin, Bosch Rexroth, Eaton, and Cylinder Service. These manufacturers have earned their reputations by producing robust, reliable, and high-performance hydraulic cylinders tailored to the needs of various industries.

For instance, Parker Hannifin, a global leader in motion and control technologies, offers a wide range of hydraulic cylinders designed for different applications, including mobile, industrial, and aerospace uses. Their products are known for their durability and efficiency, providing solutions that enhance productivity while minimizing downtime.

Similarly, Bosch Rexroth is recognized for its innovative hydraulic solutions

. The company employs advanced technologies such as smart sensors and IoT integration in its hydraulic cylinders, enabling real-time monitoring and optimization of system performance. This not only improves operational efficiency but also aids in predictive maintenance, reducing the likelihood of unexpected failures.Innovation and Trends

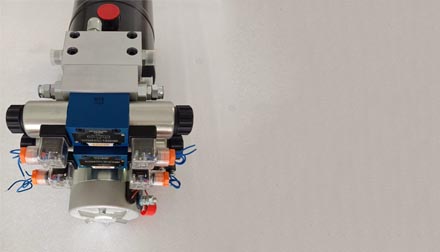

model hydraulic cylinder companies

The hydraulic cylinder industry is continuously evolving, driven by the need for greater efficiency and sustainability. One significant trend is the integration of smart technology into hydraulic systems. Modern hydraulic cylinders are increasingly equipped with sensors and digital control systems that enable users to monitor performance metrics remotely. This innovation allows for more precise control and improves overall system reliability.

Another key trend is the focus on lightweight materials. Companies are developing hydraulic cylinders made from advanced composites and high-strength alloys. These materials not only reduce the weight of the cylinders but also enhance their strength and corrosion resistance, making them suitable for harsh environments.

Additionally, customization has become a critical factor in the hydraulic cylinder market. As industries face unique challenges, manufacturers are offering tailored solutions to meet specific requirements. This may involve modifications in size, capacity, or functionality, allowing companies to optimize their operations more effectively.

The Importance of Quality and Standards

Quality assurance is paramount for hydraulic cylinder manufacturers. Compliance with international standards, such as ISO 9001 and ISO 14001, ensures that products meet stringent quality and environmental management requirements. Companies that prioritize quality not only build trust with their customers but also contribute to safety and efficiency in their applications.

Reputable manufacturers also conduct rigorous testing on their hydraulic cylinders, including pressure tests, leak tests, and endurance tests. These quality control measures help ensure that the cylinders can withstand the demanding conditions of their operational environments.

The Future of Hydraulic Cylinder Companies

Looking ahead, the future of hydraulic cylinder companies appears promising. With the rise of automation and Industry 4.0, the demand for advanced hydraulic solutions is expected to grow. Companies that embrace innovation and sustainability will be well-positioned to thrive in this competitive landscape. As industries continue to prioritize efficiency, the role of hydraulic cylinders will remain crucial in driving productivity and enhancing performance.

In conclusion, the hydraulic cylinder sector is characterized by a diverse array of companies dedicated to delivering high-quality products and innovative solutions. The ongoing evolution of technology and the increasing demand for customized, efficient systems will significantly shape the future of hydraulic cylinders, solidifying their place as vital components in various industrial applications.

-

China Carbon Fiber Hydraulic Cylinder Light & Durable

NewsJun.05,2025

-

Premium T5 Hydraulic Slave Cylinder Factories Quality Production

NewsJun.05,2025

-

Wingspan Power Unit Company Efficient Power Solutions for Industry

NewsJun.04,2025

-

High-Performance Wingspan Power Unit Products Energy Solutions

NewsJun.04,2025

-

Premium Curved Hydraulic Cylinders Durability & Precision

NewsJun.04,2025

-

Heavy-Duty 3x8 Hydraulic Cylinder Premium Industrial Solution

NewsJun.04,2025