Nov . 29, 2024 10:23 Back to list

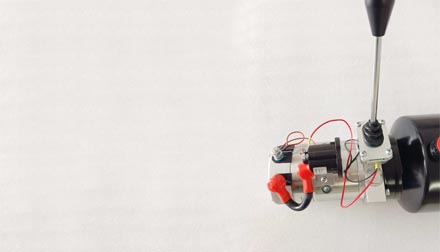

Mini Hydraulic Cylinder Manufacturers and Suppliers for Efficient Industrial Solutions

Mini Hydraulic Cylinder Factories A Growing Industry

In recent years, the demand for mini hydraulic cylinders has surged due to their versatility and effectiveness across various applications. These small yet powerful devices are integral to multiple industries, including automotive, aerospace, construction, and agriculture. The rise in the utilization of mini hydraulic cylinders has paved the way for numerous specialized factories dedicated to their production. This article delves into the importance of mini hydraulic cylinder factories, the manufacturing processes involved, and their contribution to the economy.

Understanding Mini Hydraulic Cylinders

To appreciate the role of mini hydraulic cylinder factories, it is essential to first understand what mini hydraulic cylinders are. A mini hydraulic cylinder is a compact device that converts hydraulic energy into mechanical force. Typically, these cylinders operate using a fluid, which is pressurized within a chamber to create movement. Their compact size makes them ideal for applications where space is limited, while still delivering significant power, making them essential components in various machinery.

The Significance of Mini Hydraulic Cylinder Factories

Mini hydraulic cylinder factories play a vital role in meeting the burgeoning demand for these products. As industries evolve and technologies advance, the need for innovative solutions grows exponentially. Factories specialized in mini hydraulic cylinders are increasingly focusing on producing high-quality, reliable products that meet specific customer requirements. With advancements in manufacturing techniques, these factories have also been able to enhance both the efficiency and precision of the cylinders they produce.

Moreover, mini hydraulic cylinder factories contribute significantly to local economies. They create job opportunities in manufacturing, engineering, and assembly roles. Additionally, these factories often form partnerships with local suppliers, further stimulating economic growth in the region. The collaboration between mini hydraulic cylinder factories and local businesses fosters a robust supply chain, which is vital for the overall success of industries relying on hydraulic components.

Manufacturing Processes

mini hydraulic cylinder factories

The manufacturing process of mini hydraulic cylinders is complex and requires advanced technology. Factories utilize various techniques, including precision machining, casting, and welding, to create these components. The production begins with high-quality raw materials, such as aluminum or stainless steel, which are chosen for their strength and resistance to corrosion.

Once the materials are procured, the first step typically involves machining the cylinder body to ensure exact specifications. This is followed by the assembly of internal components, including seals and pistons, which are crucial for maintaining pressure and preventing leaks. Factories have increasingly adopted automation and computer numerical control (CNC) technology to enhance precision in these processes. This shift has not only improved quality but also streamlined production times.

Quality control is paramount in the manufacturing of mini hydraulic cylinders. Factories implement rigorous testing protocols to ensure that each cylinder can withstand high pressure and perform consistently under various conditions. This focus on quality ensures that industries can rely on these components in critical applications, reducing the risk of malfunctions that could lead to costly downtimes.

Future Trends

The future of mini hydraulic cylinder factories looks promising, with several trends shaping the industry. One notable trend is the push towards sustainability. Many factories are adopting eco-friendly practices, such as using recyclable materials and minimizing waste in their manufacturing processes. As global industries face increasing pressure to reduce their ecological footprint, factories that adopt sustainable practices will likely gain a competitive edge.

Another significant trend is the integration of smart technologies. With the rise of the Internet of Things (IoT), factories are exploring ways to incorporate sensors and data analytics into their products. This innovation can enhance the performance of mini hydraulic cylinders, allowing for real-time monitoring and predictive maintenance, thereby improving operational efficiency for end users.

Conclusion

Mini hydraulic cylinder factories are crucial to the supply chain of various industries, providing essential components that drive machinery and equipment. As the demand for these cylinders continues to rise, factories are poised to meet this need through innovation, efficiency, and a commitment to quality. By embracing sustainability and smart technologies, the future of mini hydraulic cylinder manufacturing holds exciting potential, making these factories not just manufacturers, but also partners in industrial advancement.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025