Aug . 12, 2024 22:16 Back to list

Manufacturers Specializing in Dual Hydraulic Cylinders for Industrial Applications and Solutions

The Role of Dual Hydraulic Cylinder Factories in Modern Industrial Applications

In today's fast-paced industrial landscape, the need for efficient and reliable machinery is paramount. One of the key components that play a significant role in various applications is the hydraulic cylinder. Among them, dual hydraulic cylinders have gained popularity for their ability to provide enhanced force and stability in a range of operations. This article delves into the importance of dual hydraulic cylinder factories, exploring their manufacturing processes, benefits, and impact on modern engineering.

Understanding Dual Hydraulic Cylinders

Dual hydraulic cylinders consist of two interconnected cylinders that work in tandem, allowing for synchronized movement and increased force output. This design is particularly advantageous in applications where heavy loads need to be lifted, pushed, or pulled with precision and stability. Common uses include construction equipment, marine applications, and even certain automotive systems.

Manufacturing Process

The production of dual hydraulic cylinders involves several critical steps, and factories specializing in their manufacture adhere to strict quality control standards. The process typically begins with the selection of high-grade materials, often including carbon steel or aluminum, which are chosen for their durability and resistance to wear and corrosion.

Once the materials are procured, they undergo shaping and machining processes. Precision cutting tools and CNC (Computer Numerical Control) machines are often employed to ensure that the components are manufactured to exact specifications. This step is crucial because even minor deviations can lead to failures in performance, particularly given the high pressure at which hydraulic systems operate.

The subsequent phases of manufacturing include assembly, where the two cylinders are expertly joined, and sealing, which is paramount to prevent hydraulic fluid leaks

. Factories employ skilled technicians to meticulously assemble each unit, ensuring that all components function harmoniously.dual hydraulic cylinder factories

Quality assurance is a non-negotiable aspect of dual hydraulic cylinder production. Factories conduct rigorous testing procedures, including pressure tests and functionality assessments, to ensure that each cylinder can withstand operational demands. Only after passing these tests are the cylinders approved for distribution, reflecting a commitment to excellence and reliability.

Benefits of Dual Hydraulic Cylinders

The advantages of dual hydraulic cylinders are numerous and appeal to various industries. One of the primary benefits is the significant increase in lifting capacity when compared to single-cylinder systems. This allows machinery to handle heavier loads safely and efficiently, which can lead to enhanced productivity.

Additionally, the synchronized movement of dual cylinders minimizes the risk of hydraulic imbalance, which can often lead to equipment failure or safety hazards. The additional stability provided by dual systems results in more controlled operation, which is especially important in environments where precision is critical, such as in aerospace or heavy machinery applications.

Impact on Industry

As industries continue to evolve, the demand for innovative hydraulic solutions grows. Dual hydraulic cylinder factories play a crucial role in meeting this demand by providing high-quality, dependable products that empower engineers and operators alike. By investing in technology and practices that enhance manufacturing efficiency, these factories contribute to the overall progress of sectors such as construction, manufacturing, and transportation.

In conclusion, dual hydraulic cylinder factories serve as the backbone of many industries, enabling the creation of powerful, efficient, and reliable machinery. Their commitment to precise manufacturing, quality control, and continuous improvement directly impacts the safety and effectiveness of hydraulic systems in use today. As technological advancements continue to unfold, the role of these specialized factories will only grow, shaping the future of industrial innovation.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

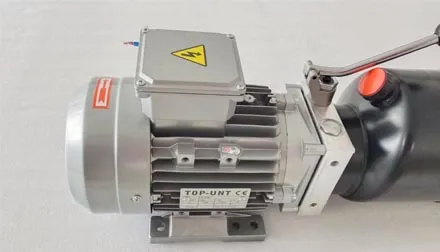

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025