Oct . 30, 2024 23:57 Back to list

manual hydraulic pump cylinder factories

Manual Hydraulic Pump Cylinder Factories An Overview

In the realm of industrial machinery, manual hydraulic pump cylinders play a pivotal role in various applications, from construction to manufacturing processes. These components are vital for generating the hydraulic force required to lift heavy loads and operate other machinery. This article will delve into the characteristics of manual hydraulic pump cylinder factories, detailing their operations, production processes, and significance in the industry.

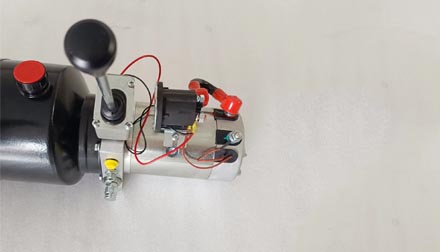

Manual hydraulic pump cylinders are devices that utilize manual labor to create hydraulic pressure through a pump mechanism, usually operated by a hand lever or pedal. Unlike electric hydraulic pumps, manual pumps are preferred for applications where electricity is unavailable or where a more controlled lifting method is required. Their simplicity and reliability make them indispensable tools in many settings, including workshops, automotive repair shops, and construction sites.

The factories that manufacture these hydraulic pump cylinders are equipped with specialized machinery and technology. The production process begins with the sourcing of high-quality raw materials, often steel or aluminum, which provide the necessary strength and durability for the cylinders. These materials undergo strict quality control measures to ensure their efficacy and safety in high-pressure applications.

Once the raw materials are secured, the manufacturing process continues with cutting, shaping, and welding. These steps shape the cylinder's body and components. Advanced CNC (Computer Numerical Control) machines are often employed to ensure precision in cutting and shaping. After the initial fabrication, the components are assembled, which involves fitting together several parts like the pump handle, cylinder body, and seals that maintain hydraulic pressure.

manual hydraulic pump cylinder factories

Post-assembly, rigorous testing is crucial to ensure the functionality and reliability of the hydraulic pump cylinders

. This typically includes pressure testing, where the assembled pump is subjected to extreme pressure conditions to check for leaks or failures. Factories must adhere to industry standards and regulations to guarantee their products are safe for consumer use.Moreover, manual hydraulic pump cylinder factories often emphasize sustainability and efficiency in their operations. They are increasingly adopting eco-friendly practices, such as recycling scrap metal produced during the manufacturing process and reducing waste through streamlined production techniques. This not only helps the environment but also reduces operational costs, allowing for more competitive pricing in the market.

The market for manual hydraulic pump cylinders is expanding, driven by increased demand across various sectors. As industries evolve and seek efficient, reliable solutions for heavy lifting and mechanical operations, the role of hydraulic technology becomes increasingly crucial. Consequently, factories producing these cylinders are poised to grow, expanding their workforce and capabilities to meet the rising demand.

In conclusion, manual hydraulic pump cylinder factories are essential contributors to the industrial landscape, merging technology with practical applications to create products that ensure efficiency and safety. As industries continue to grow and evolve, the significance of these factories and the products they produce will undoubtedly remain a cornerstone of reliable hydraulic solutions.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025