Nov . 01, 2024 09:13 Back to list

Hydraulic Cylinder Production Process in Manual Manufacturing Facilities

The Evolution and Importance of Manual Hydraulic Cylinder Factories

In the realm of industrial machinery, hydraulic systems play a crucial role, powering countless applications across various sectors. Among these, manual hydraulic cylinders stand out for their simplicity, efficiency, and reliability. Factories dedicated to the production of these essential components have been pivotal in the advancement of numerous industries, from construction to automotive. In this article, we'll explore the significance of manual hydraulic cylinder factories, their manufacturing processes, and their role in modern industry.

Manual hydraulic cylinders operate on the principle of fluid mechanics, utilizing pressurized hydraulic fluid to generate force. This enables them to lift, push, or pull heavy loads with minimal manual effort. These cylinders are user-friendly; operators can easily control the operation through a manual pump. This simplicity makes them an attractive choice for small-scale operations and applications where electricity or complex machinery is impractical.

The Evolution and Importance of Manual Hydraulic Cylinder Factories

Quality control is imperative in this manufacturing process. Factories employ stringent testing measures to ensure every cylinder meets safety and performance standards. This includes hydrostatic testing, where cylinders are subjected to high-pressure fluid tests to identify any leaks or weaknesses. Such rigorous testing not only ensures the safety of the product but also builds trust among consumers who depend on these cylinders for their operations.

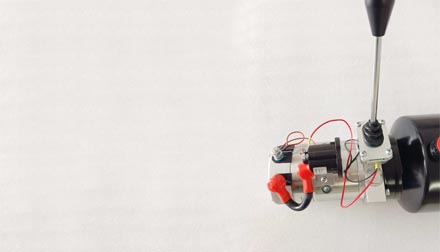

manual hydraulic cylinder factory

Additionally, manual hydraulic cylinder factories often offer customization options to meet specific client needs. This flexibility allows manufacturers to cater to diverse industries with unique requirements, from the construction of skyscrapers to the operation of mobile lifting equipment. Customized solutions can include varying sizes, stroke lengths, and pressure ratings, providing enhanced functionality for specialized applications.

The significance of these factories extends beyond just manufacturing; they are integral to local economies by providing jobs and supporting the supply chain. Skilled workers, including engineers and technicians, are essential for the design, assembly, and testing of hydraulic cylinders. Moreover, manual hydraulic cylinder factories often collaborate with other local industries, creating a symbiotic relationship that fosters innovation and growth.

As technology evolves, the future of manual hydraulic cylinder production looks promising. Automation and advanced machining technologies are gradually being integrated into traditional manufacturing processes, enhancing efficiency and precision. However, the inherent demand for manual cylinders remains strong, especially in sectors where manual operation is preferred or necessary.

In conclusion, manual hydraulic cylinder factories represent a vital component of the manufacturing landscape. Their ability to produce reliable and efficient hydraulic solutions underscores the essential role they play in various industries. As these factories continue to innovate and adapt to changing market demands, they will ensure that manual hydraulic systems remain a cornerstone of industrial operations, providing the necessary power and control to drive progress in a wide array of applications.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025