Nov . 27, 2024 09:48 Back to list

Leading Manufacturer of High-Performance Long Travel Hydraulic Cylinders for Various Applications

Long Travel Hydraulic Cylinder Manufacturers Revolutionizing Heavy Machinery

In the world of heavy machinery, hydraulic systems play a pivotal role in ensuring efficient operation and superior performance. Among the many components that make up these hydraulic systems, long travel hydraulic cylinders stand out due to their unique capabilities and applications. Manufacturers specializing in these cylinders have become vital players in industries ranging from construction to manufacturing, offering state-of-the-art solutions tailored to meet diverse operational needs.

Understanding Long Travel Hydraulic Cylinders

Long travel hydraulic cylinders are designed to provide extended linear motion that exceeds traditional hydraulic cylinders. Their design allows for significant movement, making them indispensable in applications that involve lifting, pressing, or moving heavy loads over considerable distances. These cylinders typically consist of a cylinder barrel, piston, rod, and end caps, all constructed from high-strength materials to withstand the considerable pressures exerted during operation.

One of the most significant advantages of long travel hydraulic cylinders is their ability to maintain precise control over load movement. This precision is critical in applications such as high-rise construction where heavy materials need to be lifted to great heights without sacrificing stability. Similarly, in manufacturing settings where automation is prevalent, these cylinders contribute to the efficiency of production lines by enabling smooth and controlled movements.

The Role of Manufacturers

Manufacturers of long travel hydraulic cylinders are pivotal in advancing technology in this sector. They invest in research and development to improve the design, performance, and durability of their products. The latest innovations include the use of advanced materials, such as high-strength alloys and corrosion-resistant finishes, which enhance the longevity and reliability of hydraulic cylinders.

Moreover, manufacturers often provide customization options to suit specific operational requirements. This could involve altering the size, stroke length, or pressure ratings of hydraulic cylinders to match the needs of particular machines or processes. Such flexibility makes long travel hydraulic cylinders versatile components that can be integrated into various systems, further enhancing their appeal to industries looking for tailored solutions.

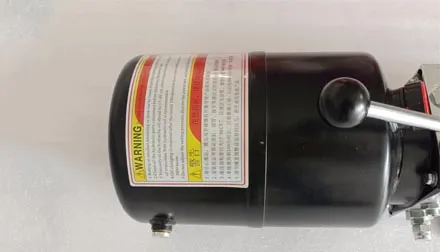

long travel hydraulic cylinder manufacturer

Quality Assurance and Standards

Quality assurance is a significant focus for reputable manufacturers of long travel hydraulic cylinders. These companies adhere to international safety and quality standards, ensuring that their products can withstand the rigors of demanding environments. Regular testing and certification processes are crucial in this regard, as they help mitigate the risk of cylinder failure, which can lead to costly downtimes and hazardous situations.

Additionally, many manufacturers implement stringent supply chain management practices to guarantee that all components meet high-quality benchmarks. This comprehensive approach to quality not only reinforces the reliability of their products but also cultivates trust among customers and end-users.

The Future of Long Travel Hydraulic Cylinder Manufacturing

As industries evolve and the demand for efficient, sustainable solutions continues to grow, the future of long travel hydraulic cylinder manufacturing looks promising. Innovations such as IoT integration for predictive maintenance and the development of energy-efficient hydraulic systems are on the horizon. These advancements aim to reduce operational costs and minimize environmental impact, aligning with global sustainability goals.

Furthermore, the advent of automation and robotics in various sectors is expected to drive the demand for highly efficient hydraulic systems, including long travel cylinders. As machines become smarter, the precision and control offered by these cylinders will be integral to maintaining productivity in automated workflows.

Conclusion

In conclusion, long travel hydraulic cylinder manufacturers play a crucial role in advancing heavy machinery technology. Their commitment to innovation, quality, and customization ensures that industries can rely on these essential components to enhance their operational efficiency. As the demand for robust and versatile engineering solutions continues to rise, these manufacturers will undoubtedly remain at the forefront of driving progress in hydraulic systems, paving the way for a more efficient and sustainable future in heavy machinery and beyond.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025