Aug . 06, 2024 09:36 Back to list

Leading Manufacturers of Hydraulic Slave Cylinders for Clutch Systems in Automotive Industries

The Importance of Clutch Hydraulic Slave Cylinder Companies in Automotive Engineering

In the realm of automotive engineering, the clutch hydraulic slave cylinder plays a pivotal role in ensuring optimal performance of vehicles, particularly those equipped with manual transmissions. This crucial component not only facilitates smooth gear shifts but also enhances the overall driving experience. As the automotive industry evolves, the demand for high-quality clutch hydraulic slave cylinders has surged, leading to the emergence of numerous companies specializing in this niche market.

Understanding the Clutch Hydraulic Slave Cylinder

Before delving into the companies that manufacture clutch hydraulic slave cylinders, it is essential to understand what this component does. The hydraulic slave cylinder is a part of the hydraulic system utilized in a vehicle's clutch mechanism. It operates by using hydraulic fluid pressure to disengage the clutch when the driver presses the pedal, allowing for seamless gear changes. This system is particularly favored in modern vehicles due to its efficiency and reliability compared to traditional mechanical linkage systems.

The Rise of Specialized Companies

As the automotive sector continues to advance, several companies have emerged as leaders in the production of clutch hydraulic slave cylinders. These companies focus on innovation, quality, and reliability to meet the stringent requirements of automotive manufacturers and ensure customer satisfaction.

1. Global Reach Many of these companies operate on a global scale, supplying automotive manufacturers across various continents. This international presence allows for the exchange of technological advancements and fosters competition, which ultimately benefits consumers.

clutch hydraulic slave cylinder companies

2. Innovative Technologies Leading companies invest heavily in research and development to produce state-of-the-art hydraulic slave cylinders. Innovations such as improved seals, lightweight materials, and advanced manufacturing processes have significantly enhanced the performance and longevity of these components.

3. Quality Assurance Quality control is a paramount focus for clutch hydraulic slave cylinder manufacturers. Many companies adhere to international standards, such as ISO 9001, to ensure that their products are durable and dependable. Rigorous testing processes, including performance and fatigue testing, are employed to guarantee that each cylinder meets the high expectations of both manufacturers and end-users.

4. Customization and Adaptability One of the hallmark features of successful companies in this field is their ability to offer customized solutions. Understanding that different vehicles may require specific designs, leading manufacturers work closely with automotive engineers to develop products tailored to unique specifications. This adaptability allows for enhanced performance within various vehicle models.

5. Sustainability Initiatives As environmental concerns rise, many companies are taking proactive steps towards sustainability. This includes sourcing eco-friendly materials, implementing energy-efficient manufacturing processes, and focusing on product longevity to reduce waste.

Conclusion

Clutch hydraulic slave cylinder companies play an indispensable role in the modern automotive landscape. Their commitment to innovation, quality, and customization ensures that vehicles operate efficiently and safely. As the industry moves toward electric and hybrid vehicles, these companies are likely to continue evolving, adapting their products to meet new challenges and maintaining their critical place in automotive engineering. The future looks promising for clutch hydraulic slave cylinder manufacturers, especially those willing to embrace technological advancements and sustainability practices while meeting the dynamic needs of the automotive sector.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

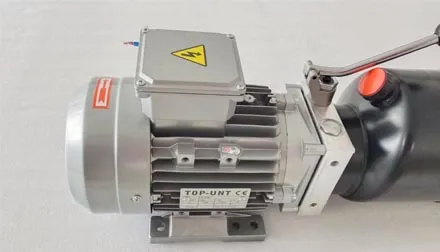

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025