Jul . 23, 2024 14:51 Back to list

Leading Manufacturer of High-Quality Large Diameter Hydraulic Cylinders for Diverse Industrial Applications

The Significance of Large Diameter Hydraulic Cylinder Manufacturers

In the realm of industrial machinery and construction equipment, large diameter hydraulic cylinders play a pivotal role in facilitating heavy lifting and moving operations. These robust components are integral to the functionality of cranes, excavators, and various hydraulic systems. The demand for high-quality large diameter hydraulic cylinders has led to the emergence of specialized manufacturers dedicated to producing these essential components. In this article, we will explore the significance of large diameter hydraulic cylinder manufacturers, their production processes, and their impact on various industries.

Understanding Large Diameter Hydraulic Cylinders

Large diameter hydraulic cylinders are hydraulic actuators used to convert hydraulic energy into mechanical energy, primarily used to lift or move heavy loads. These cylinders are characterized by their wide bore diameter, which allows them to generate substantial force in a compact design. They are commonly found in applications such as civil engineering projects, mining operations, marine applications, and heavy machinery. The ability of these cylinders to withstand high pressures while offering reliability and efficiency makes them indispensable in modern industrial applications.

Importance of Specialized Manufacturers

With the growing demand for large diameter hydraulic cylinders, manufacturers are focusing on developing advanced production techniques and materials. The specialization in manufacturing these cylinders ensures that the products meet various industry standards and regulations. Manufacturers invest in research and development to innovate designs that enhance the performance, longevity, and safety of hydraulic cylinders.

One of the key advantages of specialized large diameter hydraulic cylinder manufacturers is their ability to provide customized solutions. Each industry may have distinct requirements based on operating conditions, load capacities, and environmental factors. A proficient manufacturer can tailor designs to meet these specific needs, offering enhanced performance and satisfaction to end-users.

Production Processes

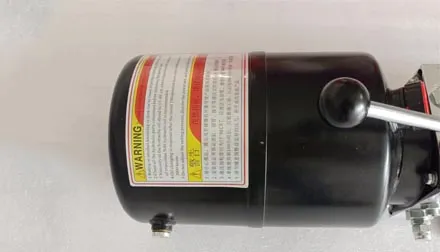

large diameter hydraulic cylinder manufacturer

The production of large diameter hydraulic cylinders involves several key steps, each crucial to ensuring the final product's quality and reliability. The process generally begins with choosing the right materials, typically high-strength steel or advanced alloys, which offer durability and resistance to wear and tear. Next, precision machining is employed to create the cylinder's bore, ensuring it meets the necessary specifications for performance.

Welding and assembly processes follow, where the cylinder components are joined together. The expertise of skilled technicians is paramount in this phase, as improper welding can lead to structural weaknesses and failures. After assembly, cylinders undergo rigorous testing, including pressure tests and performance evaluations, to confirm they can withstand the operational demands they will face in real-world applications.

Impact on Industries

The quality and reliability of large diameter hydraulic cylinders directly impact various industry sectors. In construction, for example, the efficiency of cranes and excavators hinges on the performance of hydraulic cylinders. Reliable cylinders enhance productivity and safety on job sites, minimizing downtime and the risk of accidents.

In the mining industry, robust hydraulic cylinders are essential for equipment used in the extraction and transportation of ores. Their durability in harsh environments contributes to a smoother operation and reduces maintenance costs. Similarly, in marine applications, hydraulic cylinders are crucial for operating equipment such as ship cranes and dredging machines, where failure could have catastrophic consequences.

Conclusion

In conclusion, large diameter hydraulic cylinder manufacturers play a vital role in the manufacturing landscape, providing crucial components that enable a wide array of industrial applications. Their commitment to quality, customization, and innovation significantly enhances the performance and safety of hydraulic systems. As industries continue to evolve and expand, the importance of specialized manufacturers will only grow, helping to propel advancements in engineering and technology. Investing in high-quality large diameter hydraulic cylinders is not merely a choice; it is a necessity for achieving efficiency and reliability in demanding applications.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025