Dec . 03, 2024 10:41 Back to list

hydraulic slave cylinder manufacturer

The Role of Hydraulic Slave Cylinder Manufacturers in Modern Engineering

In contemporary engineering practices, hydraulic systems play a critical role in various applications, ranging from automotive to industrial machinery. Among the essential components of these systems is the hydraulic slave cylinder. This article delves into the significance of hydraulic slave cylinder manufacturers in ensuring the efficiency and reliability of hydraulic systems.

Understanding Hydraulic Slave Cylinders

A hydraulic slave cylinder is a type of actuator that converts hydraulic energy into mechanical motion. It is typically used in applications where precise movement is necessary, such as in braking systems in vehicles, clutches, and numerous industrial operations. The slave cylinder operates by receiving hydraulic fluid from the master cylinder, which generates pressure that pushes the piston within the slave cylinder, thereby translating hydraulic pressure into motion.

The operational efficacy of hydraulic slave cylinders is paramount. If they malfunction, it can lead to performance issues such as reduced braking efficiency, compromised safety, or even catastrophic equipment failure. Therefore, the quality and reliability of these components are crucial, making the role of manufacturers indispensable in the supply chain of hydraulic systems.

The Responsibilities of Hydraulic Slave Cylinder Manufacturers

Manufacturers of hydraulic slave cylinders must adhere to stringent quality standards to ensure the safety and effectiveness of their products. Key responsibilities include

1. Design and Engineering Manufacturers must employ skilled engineers who can design cylinders that meet specific application requirements. This involves understanding the force requirements, operating environment, and compatibility with hydraulic fluids.

2. Material Selection The choice of materials is pivotal. Hydraulic slave cylinders must withstand high pressures and resist corrosion and wear. Manufacturers often utilize high-strength alloys, stainless steel, or composite materials to enhance durability.

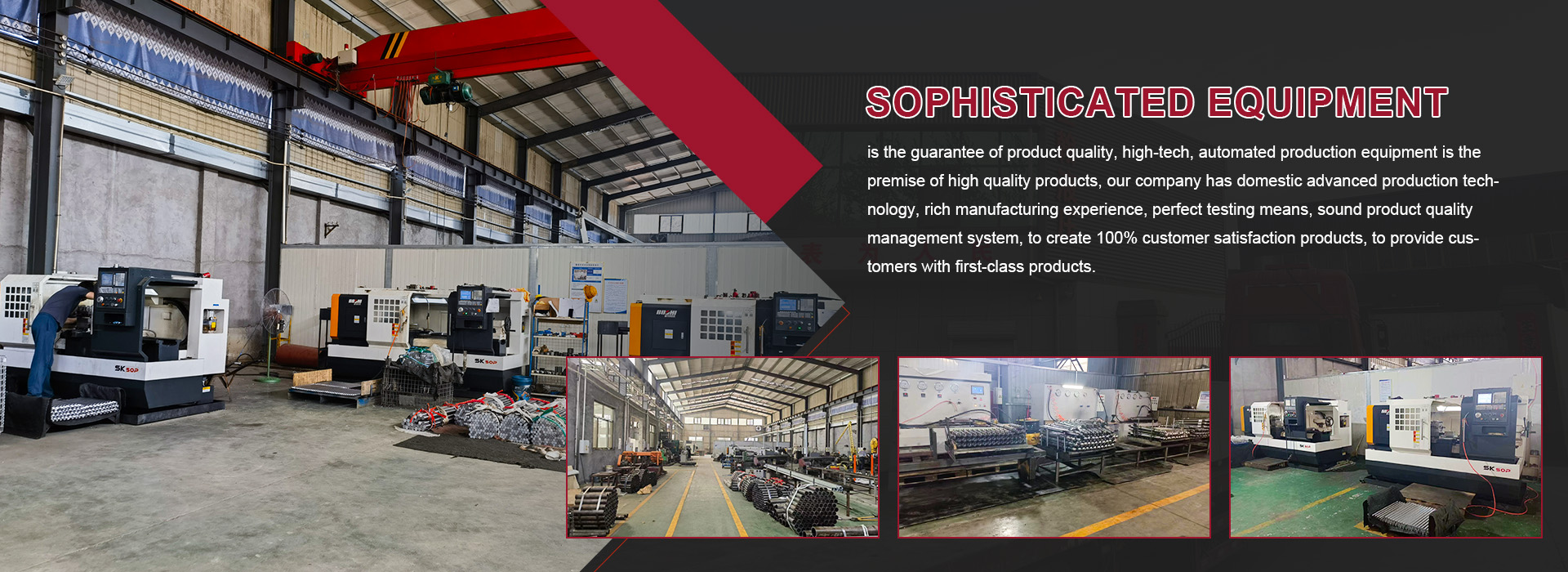

3. Precision Manufacturing Advanced manufacturing techniques such as CNC machining, welding, and heat treatment ensure that each cylinder meets precise specifications. Tolerances must be tightly controlled to prevent leaks and ensure optimal performance.

hydraulic slave cylinder manufacturer

4. Quality Assurance Comprehensive testing protocols are essential. Manufacturers conduct hydraulic testing, pressure testing, and endurance tests to verify that the cylinders perform under expected conditions. Certifications from recognized bodies help assure customers of product reliability and safety.

5. Customization and Innovation With evolving technology and demands, manufacturers must be flexible in their approach. Custom solutions tailored to specific application needs can give a competitive edge. Moreover, investing in research and development can lead to innovations that improve performance, efficiency, and safety.

The Impact on Industries

The implications of hydraulic slave cylinder manufacturing extend across several industries. In the automotive sector, these components enhance vehicle safety and performance. In industrial applications, they facilitate automation and improve operational efficiencies.

For instance, in heavy machinery, hydraulic slave cylinders are critical in lifting and moving loads safely. They enhance the precision of movements in construction equipment, making tasks like excavation and lifting remarkably more efficient and safe. In the aerospace industry, they play an essential role in controlling flight surfaces and landing gear, where reliability is non-negotiable.

Future Trends in Hydraulic Slave Cylinder Manufacturing

As technology evolves, so does the field of hydraulic slave cylinder manufacturing. The integration of smart technologies and IoT (Internet of Things) is beginning to influence the design of hydraulic systems. Manufacturers are exploring options that include sensors and data analytics to monitor cylinder performance in real-time, predictive maintenance capabilities, and improved safety features.

Additionally, there is a growing emphasis on sustainability within the manufacturing process. This includes using environmentally friendly materials and processes, reducing waste, and exploring alternative hydraulic fluids that have a lower environmental impact.

Conclusion

Hydraulic slave cylinder manufacturers play a fundamental role in the effectiveness and reliability of hydraulic systems across various applications. By focusing on quality, precision engineering, and innovative practices, these manufacturers ensure that the critical components they produce not only meet but exceed industry standards. As we look to the future, the importance of these manufacturers will only continue to grow, reinforcing their vital place within the engineering landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025