Dec . 10, 2024 05:10 Back to list

hydraulic ramp cylinder factories

The Role of Hydraulic Ramp Cylinder Factories in Modern Industries

In today's fast-paced industrial landscape, efficiency and precision are critical components of operational success. One vital contributor to this efficiency is the hydraulic ramp cylinder, a hydraulic actuator designed to perform various lifting and lowering tasks in industries ranging from construction to manufacturing. The importance of hydraulic ramp cylinder factories cannot be overstated, as they are responsible for producing these essential components that drive a wide array of machinery.

Understanding Hydraulic Ramp Cylinders

Hydraulic ramp cylinders function by utilizing pressurized hydraulic fluid to create movement. These cylinders can lift heavy loads with relative ease compared to mechanical systems, making them indispensable in scenarios where space or weight is a constraint. Industries often employ these cylinders in applications such as loading docks, car lifts, and conveyor systems. The ability to handle significant weight while maintaining precision demonstrates the remarkable engineering behind these hydraulic systems.

The Manufacturing Process

The process of manufacturing hydraulic ramp cylinders is intricate and requires specialized facilities. Factories engaged in this production typically utilize advanced technology and skilled labor to ensure each cylinder meets the required safety and performance standards. The production begins with high-quality material selection, usually steel or aluminum, known for their durability and strength.

Once the materials are chosen, advanced machining processes, such as CNC (Computer Numerical Control) machining, come into play. This technology allows for precise cuts and designs, ensuring the components fit together perfectly, which is critical for the efficient operation of hydraulic systems. After machining, the cylinders undergo rigorous testing to assess their performance under pressure. Quality control is a crucial aspect of factory operations, as a single faulty cylinder can lead to catastrophic failures in heavy machinery.

Innovations in Design

hydraulic ramp cylinder factories

As technology advances, so do the designs of hydraulic ramp cylinders. Modern factories are incorporating innovations such as smart sensors and IoT (Internet of Things) capabilities. These additions allow for real-time monitoring of cylinder performance, enabling predictive maintenance and reducing downtime in industrial operations. Factories are also exploring lightweight materials and advanced coatings to improve the longevity and efficiency of hydraulic systems.

The Importance of Sustainable Practices

With the increasing awareness of environmental sustainability, many hydraulic ramp cylinder factories are adapting their practices to reduce their carbon footprint. This includes optimizing energy consumption during manufacturing processes and implementing recycling programs for scrap materials. Sustainable practices not only benefit the planet but also enhance a factory's reputation and marketability.

Challenges Facing the Industry

Despite their advancements, hydraulic ramp cylinder factories face several challenges. Fluctuations in raw material prices can impact production costs, while global competition requires manufacturers to continually innovate to stay ahead. Furthermore, regulatory compliance is becoming increasingly stringent, necessitating that factories invest in research and development to meet safety and environmental standards.

Conclusion

Hydraulic ramp cylinder factories play an essential role in the efficiency and functionality of modern machinery across various industries. As technology evolves, these factories must adapt to new challenges while maintaining high standards of quality and innovation. The ongoing evolution of hydraulic systems will continue to drive advancements in manufacturing and improve operational efficiencies, making these facilities crucial players in the industrial landscape. Investing in robust production processes and sustainable practices will ensure that hydraulic ramp cylinder factories can thrive and contribute to a more efficient future.

-

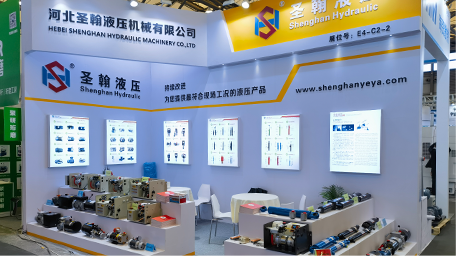

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025