Dec . 13, 2024 18:56 Back to list

hydraulic pusher cylinder company

Hydraulic Pusher Cylinder Revolutionizing Industrial Automation

Hydraulic pusher cylinders have emerged as a vital component in modern industrial applications, providing precision and efficiency in various machinery processes. The versatility of these cylinders is unmatched, making them integral to industries such as manufacturing, construction, and material handling. This article delves into the workings, applications, and benefits of hydraulic pusher cylinders, as well as the leading companies in the sector that are driving innovation and quality.

What is a Hydraulic Pusher Cylinder?

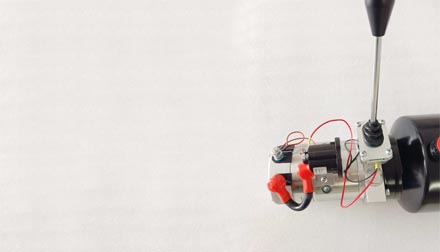

A hydraulic pusher cylinder is a mechanical actuator that converts hydraulic energy into linear motion. It is composed of several essential components, including a cylinder, piston, seals, and hydraulic fluid. When pressurized hydraulic fluid is introduced into the cylinder, it pushes the piston, creating a force that can move heavy loads and perform various tasks with incredible precision.

Hydraulic pusher cylinders are available in many configurations and sizes, allowing them to accommodate a wide range of applications—from simple pushing and pulling tasks to complex automation systems that require synchronized movements.

Applications in Various Industries

The applications of hydraulic pusher cylinders span across numerous sectors. In manufacturing, they are commonly used for assembly processes, material handling, and product testing. The automotive industry utilizes these cylinders for tasks like stamping, shaping, and assembling vehicle components, facilitating high-speed production lines while ensuring precision and safety.

In construction, hydraulic pusher cylinders are often employed in earth-moving equipment, such as bulldozers and excavators, allowing for effective pushing and lifting of heavy materials. This capability enhances productivity on site, enabling construction projects to progress smoothly and efficiently.

Material handling is another critical area where hydraulic pusher cylinders excel. In warehouses and logistics, they are used to maneuver bulk materials, operate conveyors, and facilitate the movement of goods. Their ability to apply significant force while maintaining control makes them indispensable in environments where heavy lifting and precise positioning are required.

Advantages of Hydraulic Pusher Cylinders

The advantages of hydraulic pusher cylinders contribute significantly to their adoption in various industries

. Some key benefits include1. High Force Capabilities Hydraulic systems generate a significant amount of force, allowing for the movement of heavy loads with minimal operator input. This aspect is crucial in industrial environments where heavy objects need to be moved frequently.

hydraulic pusher cylinder company

2. Precision and Control Hydraulic pusher cylinders can be calibrated for speed and position, making it easier to execute complex movements with accuracy. This precision is vital in manufacturing applications where tolerances are tight, and quality control is paramount.

3. Durability and Reliability Constructed from high-quality materials, hydraulic cylinders are designed to withstand harsh industrial conditions. Their robust build quality ensures longevity, minimizing downtime and reducing maintenance costs.

4. Versatility As mentioned earlier, the adaptability of these cylinders means they can be used in various applications. This versatility fosters innovation, allowing companies to implement them in different contexts to enhance operational efficiency.

Leading Companies in the Hydraulic Cylinder Industry

Several companies stand out in the hydraulic cylinder manufacturing sector, known for their commitment to quality and innovation. These include

- Parker Hannifin A global leader in motion and control technologies, Parker offers a comprehensive range of hydraulic cylinders, including custom solutions designed for specific applications.

- Bosch Rexroth Renowned for their advanced engineering solutions, Bosch Rexroth provides hydraulic pusher cylinders that feature cutting-edge technology, ensuring high performance and reliability.

- Eaton With a focus on sustainable energy solutions, Eaton manufactures hydraulic cylinders with an emphasis on efficiency and durability, catering to various industries.

- Sundstrand Corporation Known for their hydraulic and pneumatic systems, Sundstrand produces high-quality pusher cylinders tailored to meet the demands of modern industrial applications.

Conclusion

In conclusion, hydraulic pusher cylinders play a crucial role in today's industrial landscape, providing efficient, reliable, and precise movement solutions across various applications. Their significance cannot be overstated as industries continue to seek innovative ways to enhance productivity and maintain safety. As technology advances, the future of hydraulic pusher cylinders looks promising, paving the way for smarter and more efficient automation solutions.

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Engineering&Customization

NewsAug.07,2025

-

Turbocharged 1.5 Ton Cylinder | Model 80/95-40/60-35-124

NewsAug.07,2025

-

1.5 Ton Lifting Cylinder - Hebei Shenghan|High Load, Durable, Custom

NewsAug.06,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co. Ltd.|Precision Lifting&Heavy-Duty Performance

NewsAug.06,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Heavy-Duty Hydraulic Solutions

NewsAug.06,2025

-

1.5-Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Custom Industrial Lifting

NewsAug.06,2025