Nov . 16, 2024 13:28 Back to list

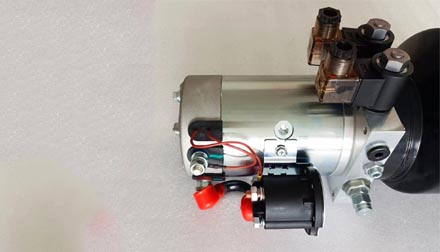

hydraulic piston and cylinder manufacturers

The Role of Hydraulic Piston and Cylinder Manufacturers in Modern Industry

Hydraulic systems play a crucial role in various industries, from construction to manufacturing to automotive. At the heart of these systems are hydraulic pistons and cylinders, which work together to convert hydraulic energy into mechanical work. As industries continue to evolve and demand more efficient, powerful, and reliable machinery, the role of hydraulic piston and cylinder manufacturers has become increasingly vital.

Understanding Hydraulic Systems

Hydraulic systems utilize pressurized fluid to produce motion and force. The hydraulic cylinder, a mechanical actuator, is responsible for converting this hydraulic energy into linear motion. At the same time, the hydraulic piston, which moves within the cylinder, is essential for creating pressure differences that drive the system. These components are vital in applications ranging from earth-moving equipment to industrial machinery, making their design and manufacturing a highly specialized field.

Key Manufacturers and Their Contributions

Hydraulic piston and cylinder manufacturers vary in size, capability, and specialization. Some of the leading companies in this sector focus on producing standard products, while others specialize in custom solutions tailored to a client's specific needs. For instance, manufacturers like Parker Hannifin, Bosch Rexroth, and Eaton are known for their high-quality hydraulic systems and components, catering to a global market.

These manufacturers invest heavily in research and development to innovate and improve their products. Advances in materials science have led to the creation of lighter yet stronger materials, enhancing the performance and longevity of hydraulic cylinders. Additionally, manufacturers are increasingly focusing on automation and digitalization, implementing smart technologies that allow for better monitoring and control of hydraulic systems.

Customization and Specialized Solutions

One of the significant trends in the hydraulic industry is the increased demand for customization. As industries face unique challenges, the need for tailored hydraulic solutions becomes more pronounced. Manufacturers are now offering bespoke designs that cater to specific applications, ensuring that customers get the most efficient performance possible.

hydraulic piston and cylinder manufacturers

For example, in the construction industry, hydraulic cylinders must withstand extreme conditions, such as high pressures and corrosive environments. Manufacturers that can produce durable and resistant cylinders will gain a competitive edge. Additionally, in sectors like aerospace and automotive, precision engineering is critical. Manufacturers have to deliver components that not only meet strict safety standards but also enhance overall performance.

Quality Standards and Regulations

Hydraulic piston and cylinder manufacturers must adhere to strict quality standards and regulations. Industries such as aerospace, automotive, and marine have specific compliance standards that manufacturers must meet. International standards such as ISO 9001 and ISO 14001 ensure that companies maintain high-quality production processes and environmental management systems.

Moreover, regular testing and certification processes are essential to guarantee the reliability and safety of hydraulic components. Manufacturers often collaborate with testing laboratories to verify that their products can withstand the rigorous demands of real-world applications.

Sustainability and Future Trends

Sustainability is an increasingly important factor for hydraulic piston and cylinder manufacturers. There is a growing push toward more eco-friendly and energy-efficient hydraulic systems. Manufacturers are exploring options such as bio-based hydraulic fluids and energy recovery systems, which can reduce the environmental impact of hydraulic operations.

Looking ahead, the integration of IoT and smart technologies promises to revolutionize hydraulic systems. Predictive maintenance and real-time monitoring capabilities will allow operators to optimize the performance and lifespan of hydraulic equipment, reducing downtime and maintenance costs.

Conclusion

In conclusion, hydraulic piston and cylinder manufacturers are essential players in the modern industrial landscape. Their ability to innovate, customize, and adhere to strict quality standards positions them as key contributors to the efficiency and reliability of hydraulic systems. As industries strive for greater sustainability and technological advancements, the future of hydraulic manufacturing will likely be defined by these ongoing changes, setting the stage for enhanced performance and environmental responsibility in the years to come.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025