Dec . 15, 2024 09:27 Back to list

hydraulic loader cylinder company

Hydraulic Loader Cylinder Company Powering Efficiency and Innovation

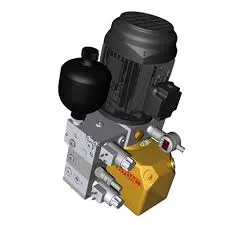

In the fast-paced world of construction and heavy machinery, hydraulic systems play an indispensable role in enhancing operational efficiency and stability. At the heart of these hydraulic systems are the hydraulic loader cylinders, essential components that enable various types of machinery to lift, move, and manipulate heavy loads with ease. This article delves into the significance of a hydraulic loader cylinder company, exploring its contributions to the industry, the technology behind hydraulic cylinders, and the future of hydraulic systems.

The Role of Hydraulic Loader Cylinders

Hydraulic loader cylinders are hydraulic actuators that convert hydraulic energy into mechanical force. These cylinders are vital for loading, unloading, digging, and various lifting tasks across construction sites, warehouses, and industrial settings. Their ability to generate substantial force while maintaining precision makes them essential for equipment like excavators, front-end loaders, and backhoes.

A hydraulic loader cylinder company specializes in manufacturing these intricate components, focusing on quality, durability, and performance. The reliability of the hydraulic cylinders is crucial; any failure can lead to significant downtime, safety hazards, and increased operational costs. Therefore, companies in this field prioritize design, materials selection, and rigorous testing to ensure their products meet industry standards.

Advancements in Hydraulic Technology

The hydraulic cylinder industry has seen remarkable advancements over recent years, driven by demands for greater efficiency, environmental sustainability, and safety. Companies are increasingly adopting innovative technologies such as computer-aided design (CAD), finite element analysis (FEA), and advanced manufacturing techniques to enhance the performance of hydraulic cylinders.

One prominent trend is the integration of smart technology into hydraulic systems. Modern hydraulic loader cylinders can now be equipped with sensors that monitor performance in real-time, providing valuable data on pressure, temperature, and wear. Such data can be used to predict maintenance needs, thus minimizing unexpected failures and prolonging the life of the equipment.

Additionally, advancements in materials science have led to the development of stronger and lighter materials for hydraulic cylinders. These improvements not only boost performance but also contribute to the overall efficiency of machinery, as lighter components reduce the energy required for lifting operations.

hydraulic loader cylinder company

Commitment to Sustainability

In today's world, sustainability is at the forefront of industrial innovation, and hydraulic loader cylinder companies are no exception. Many manufacturers are adopting eco-friendly practices, such as reducing waste in the production process and using recyclable materials. Additionally, the push for more energy-efficient hydraulic systems has resulted in the development of cylinders that require less hydraulic fluid, further minimizing environmental impact.

Furthermore, companies are focusing on producing cylinders that work with biodegradable hydraulic fluids, significantly reducing the ecological footprint in case of leaks or spills. By marrying advanced technology with sustainable practices, hydraulic loader cylinder companies are not only improving their offerings but also contributing to a greener future.

The Future of Hydraulic Systems

As the demand for smarter, more efficient machinery continues to rise, the future of hydraulic systems looks promising. With ongoing research and development, we can expect to see even more advanced hydraulic loader cylinders that incorporate artificial intelligence (AI) and machine learning. These technologies have the potential to revolutionize how hydraulic systems operate, enabling predictive maintenance, adaptive responses to load conditions, and enhanced safety features.

Moreover, the rise of electric and hybrid machinery is likely to influence the hydraulic loader cylinder industry. Companies will need to adapt their designs to cater to these new power sources while maintaining the performance and reliability that end-users expect.

Conclusion

In conclusion, hydraulic loader cylinder companies are at the forefront of innovation within the construction and heavy machinery sectors. Their commitment to quality, technological advancements, and sustainability has established them as key players in an industry that demands efficiency and reliability. As the landscape of machinery continues to evolve, these companies will undoubtedly continue to refine and enhance hydraulic systems, paving the way for a more efficient and sustainable future in heavy lifting and construction operations.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025