Sep . 21, 2024 19:45 Back to list

hydraulic feed cylinder products

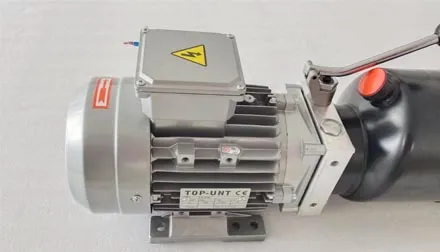

Understanding Hydraulic Feed Cylinder Products

Hydraulic feed cylinders are essential components in various industrial applications, particularly in manufacturing and automation processes. These cylinders utilize hydraulic fluid pressure to produce linear motion, enabling machines to operate efficiently and with precision. This article explores the significance, functionality, and applications of hydraulic feed cylinder products.

What are Hydraulic Feed Cylinders?

Hydraulic feed cylinders are devices that convert hydraulic energy into mechanical work. They typically consist of a cylinder, piston, and hydraulic fluid. When pressurized fluid is introduced into the cylinder, it pushes the piston, creating linear motion. This motion is crucial for processes that require precise and controlled movement, such as feeding materials into machinery or positioning tools in automated systems.

Key Features and Benefits

1. High Efficiency Hydraulic feed cylinders are designed to handle substantial loads while maintaining high efficiency. The ability to generate significant force with relatively low energy input makes them ideal for demanding applications.

2. Precision Control These cylinders offer excellent control over movement speed and positioning, which is vital in applications such as CNC machining and assembly lines. Operators can easily adjust hydraulic pressure to achieve the desired motion.

hydraulic feed cylinder products

3. Durability and Reliability Constructed from robust materials, hydraulic feed cylinders are built to withstand harsh environments and continuous usage. Their reliability minimizes downtime, ensuring continuous operation in industrial settings.

4. Versatility Hydraulic feed cylinders can be tailored to meet specific operational needs, making them suitable for a wide range of applications, from metalworking to packaging and everything in between.

Applications of Hydraulic Feed Cylinders

Hydraulic feed cylinders find applications across various industries. In manufacturing, they are commonly used in press machines, injection molding, and metal stamping. In construction, they power heavy machinery, such as excavators and loaders, enabling them to perform tasks that require significant force.

In the aerospace and automotive sectors, hydraulic feed cylinders are crucial for precision assembly and maintenance tasks. They facilitate the safe and efficient movement of components, ensuring that critical operations are completed with accuracy.

Conclusion

In summary, hydraulic feed cylinder products play a vital role in enhancing efficiency and precision in numerous industrial applications. Their design enables them to deliver high force while being adaptable to various operational requirements. As technology continues to advance, the demand for these cylinders is likely to increase, driving innovations that further enhance their performance and reliability. Whether in manufacturing, construction, or any other sector, hydraulic feed cylinders remain indispensable tools that contribute to operational success.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025