Nov . 13, 2024 23:56 Back to list

hydraulic feed cylinder factory

The Hydraulic Feed Cylinder Factory Engineering Precision and Reliability

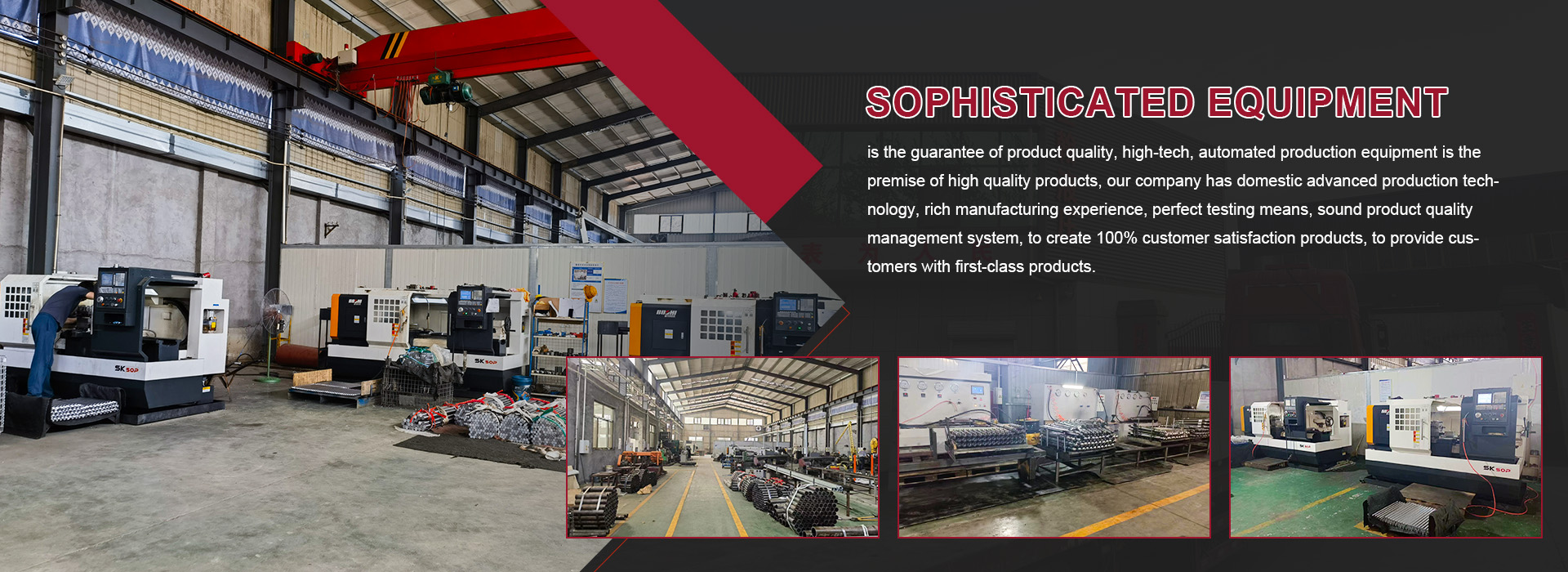

In the modern industrial landscape, the role of hydraulic systems cannot be overstated. A critical component in these systems is the hydraulic feed cylinder, which serves as a powerhouse for various applications in manufacturing and automation. At the heart of this industry lies the hydraulic feed cylinder factory, a place dedicated to the design, production, and quality assurance of these essential components.

The Importance of Hydraulic Feed Cylinders

Hydraulic feed cylinders are crucial in converting hydraulic energy into mechanical force, which is then utilized to perform various tasks, from lifting heavy materials to powering machinery. These cylinders are designed to withstand high pressures, making them ideal for industries such as automotive, construction, aerospace, and manufacturing. The efficiency and reliability of these cylinders directly impact the productivity and safety of the equipment they serve.

The Manufacturing Process

Creating high-quality hydraulic feed cylinders involves meticulous engineering and precise manufacturing processes. Here’s a breakdown of the typical steps involved in producing these vital components.

1. Design and Engineering The journey begins with the design phase, where engineers use computer-aided design (CAD) software to create accurate models. Factors like load requirements, operating environment, and desired stroke length are taken into account to ensure optimal performance.

2. Material Selection The choice of materials is crucial in ensuring the longevity and performance of the hydraulic cylinder. Common materials include high-strength steel and aluminum, which offer a combination of strength and weight savings. The material selected must also be compatible with the hydraulic fluids to be used.

3. Manufacturing Techniques After the design and material selection, the manufacturing process begins. Techniques such as machining, welding, and heat treatment are employed to create the various components of the hydraulic feed cylinder. CNC (Computer Numerical Control) machines are often used for precision machining, ensuring that each part meets exact specifications.

hydraulic feed cylinder factory

4. Assembly Once the components are manufactured, they are carefully assembled. This stage requires skilled technicians to ensure that seals, valves, and other critical components are fitted correctly to prevent leaks and ensure efficient operation.

5. Quality Control Quality assurance is paramount in the production of hydraulic cylinders. Each unit undergoes rigorous testing, including pressure testing and performance evaluations. This step is vital to ensure that each hydraulic feed cylinder meets industry standards and can withstand the stresses of operational use.

6. Finishing Touches Finally, the cylinders are painted or coated to protect against corrosion and wear. This prepares them for deployment in various environments, enhancing their durability and lifespan.

Innovations in Hydraulic Technology

The hydraulic feed cylinder factory is not just a hub for production; it is also a center for innovation. Ongoing research and development activities aim to improve the efficiency and performance of hydraulic systems. New technologies, such as smart cylinders equipped with sensors for real-time monitoring, are being developed to enhance the functionality and adaptability of hydraulic systems.

Environmental Considerations

As industries move towards more sustainable practices, the hydraulic feed cylinder factory is also embracing eco-friendly initiatives. Manufacturers are increasingly adopting sustainable materials and processes, including recycling metal scraps and using environmentally friendly coatings. Additionally, the development of more energy-efficient hydraulic systems contributes to reducing the overall carbon footprint of industrial operations.

Conclusion

The hydraulic feed cylinder factory stands as a testament to the advanced engineering and manufacturing capabilities of the modern industrial sector. With its commitment to quality, innovation, and sustainability, the factory plays a crucial role in supplying the hydraulic components that power countless machines and systems across various industries. As technology continues to evolve, these factories will adapt, ensuring that hydraulic feed cylinders remain an indispensable part of the industrial landscape. The future promises even greater advancements, further solidifying the importance of hydraulic technology in shaping efficient and reliable operations worldwide.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025