Nov . 13, 2024 20:07 Back to list

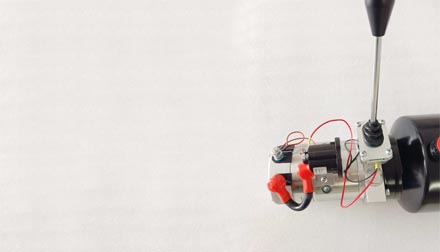

hydraulic feed cylinder factories

The Importance of Hydraulic Feed Cylinder Factories in Modern Industry

In the rapidly evolving landscape of industrial machinery, hydraulic feed cylinders have emerged as a critical component across multiple sectors. These cylinders are essential for the efficient operation of various machines, particularly in manufacturing and processing industries. As the demand for precision and performance continues to grow, so does the necessity for specialized factories dedicated to producing high-quality hydraulic feed cylinders.

Understanding Hydraulic Feed Cylinders

Hydraulic feed cylinders are devices that use hydraulic pressure to convert fluid energy into mechanical energy. They play a vital role in automating and controlling the movement of machinery and tools. Typically, these cylinders are used in applications such as metal forming, material handling, and packaging, where precise control over the movements is paramount. The ability to generate significant force while maintaining fine control makes hydraulic systems indispensable.

The Role of Hydraulic Feed Cylinder Factories

The role of hydraulic feed cylinder factories is multifaceted. First and foremost, these factories specialize in the design and manufacture of hydraulic cylinders tailored to meet specific industrial needs. They employ state-of-the-art technology and engineering practices to ensure that every cylinder meets the stringent standards required for optimal performance.

Moreover, these factories are often involved in the research and development of new technologies. As industries evolve and new challenges arise, the need for innovative hydraulic solutions becomes increasingly critical. Factories engage in R&D to enhance the functionality, durability, and efficiency of hydraulic feed cylinders, ensuring that they can handle a wide range of operational demands.

Quality Control and Standards

hydraulic feed cylinder factories

In any manufacturing process, quality control is paramount, and hydraulic feed cylinder factories are no exception. These facilities implement rigorous testing protocols to ensure that every product meets established industry standards. From material selection to fabrication and assembly, every step of the process is monitored to identify and rectify any potential deficiencies. This level of care not only enhances the performance of the cylinders but also significantly reduces the likelihood of operational failures, which can be costly and dangerous in industrial settings.

ISO standards and other certifications are often integral to the operations of these factories, serving as benchmarks for quality and performance. Manufacturers that adhere to these standards demonstrate a commitment to excellence and reliability, fostering trust among clients and partners.

Sustainability and Innovation

With increasing awareness of environmental issues, many hydraulic feed cylinder factories are adopting sustainable practices. This includes using eco-friendly materials, implementing energy-efficient manufacturing processes, and minimizing waste throughout production. By embracing sustainability, these factories not only contribute to environmental conservation but also align with the growing demand from consumers for greener, more responsible manufacturing practices.

Innovation is also a key driver within hydraulic feed cylinder factories. The integration of smart technology, such as IoT (Internet of Things) and AI (Artificial Intelligence), is revolutionizing the way hydraulic systems operate. These technologies enable real-time monitoring and predictive maintenance, enhancing efficiency and reducing downtime in industrial operations. Factories that harness these innovations position themselves at the forefront of the market, offering products that are not only reliable but also equipped for the challenges of tomorrow.

Conclusion

Hydraulic feed cylinder factories play a pivotal role in the modern industrial ecosystem. Their contributions to quality manufacturing, innovation, and sustainability are crucial for meeting the demands of an increasingly competitive market. As industries continue to evolve, the importance of these specialized facilities will only grow, paving the way for advancements that enhance productivity and safety across various sectors. Investing in reliable hydraulic feed cylinders and supporting the factories that produce them is essential for any business looking to optimize its operations and maintain a competitive edge.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025