Oct . 07, 2024 09:13 Back to list

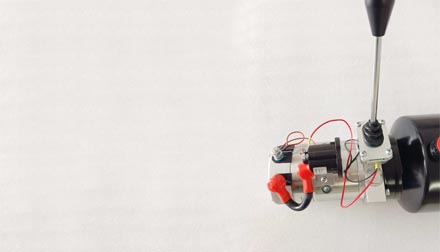

hydraulic downfeed control cylinder products

Understanding Hydraulic Downfeed Control Cylinder Products

Hydraulic downfeed control cylinders are essential components in various industrial applications. Their ability to precisely control the movement and force exerted by machinery makes them invaluable in fields ranging from manufacturing to construction. This article explores the functionality, benefits, and applications of hydraulic downfeed control cylinders, offering a comprehensive overview for those interested in this technology.

What is a Hydraulic Downfeed Control Cylinder?

A hydraulic downfeed control cylinder is a type of actuator that utilizes hydraulic fluid to create mechanical motion. It converts hydraulic energy into linear motion, allowing machines to exert force in a controlled manner. This technology is particularly useful for processes that require high levels of precision, such as metalworking and woodworking.

These cylinders are designed to allow for smooth, adjustable movement rates, which is crucial when handling sensitive materials that can be damaged by excessive force or speed. They can be integrated into various machinery, including presses, saws, and lathes, to facilitate tasks such as cutting, drilling, and shaping materials.

How Do Hydraulic Downfeed Control Cylinders Work?

The fundamental operation of a hydraulic downfeed control cylinder involves the circulation of hydraulic fluid through a series of valves and chambers. When the fluid is pressurized, it moves into the cylinder and forces the piston to move downwards. The downfeed movement can be controlled by adjusting the flow of hydraulic fluid, allowing operators to set the descent speed and pressure according to the specific needs of the operation.

Many modern hydraulic downfeed control cylinders are equipped with features such as load sensing and electronic controls, which provide real-time feedback and adjustments based on the load the cylinder is handling. This level of control not only enhances precision but also optimizes the efficiency of hydraulic systems.

Key Benefits of Hydraulic Downfeed Control Cylinders

1. Precision One of the standout features of hydraulic downfeed control cylinders is their ability to deliver precise movements. This is crucial in applications where accuracy is paramount, such as CNC machining.

2. Power Hydraulic systems are known for their ability to generate significant force in compact sizes. This means that hydraulic downfeed control cylinders can handle hefty loads without requiring excessive amounts of physical space.

3. Adjustability The ability to vary the speed and force of the downfeed allows for greater flexibility when working with different materials. Operators can fine-tune the settings to suit specific tasks, which can lead to improved outcomes and reduced material waste.

hydraulic downfeed control cylinder products

4. Durability Hydraulic systems are generally robust and well-suited for heavy-duty applications. When properly maintained, hydraulic downfeed control cylinders can have a long service life, reducing downtime and maintenance costs.

5. Consistency Once set, these cylinders can repeatedly perform tasks with consistent results, which is crucial in production environments where variability must be minimized.

Applications of Hydraulic Downfeed Control Cylinders

The versatility of hydraulic downfeed control cylinders allows them to be used in a wide range of industries. Some common applications include

- Manufacturing In factories, these cylinders are often used in automated machinery for processes such as molding, stamping, and assembly.

- Construction Hydraulic downfeed control cylinders are employed in equipment such as excavators and cranes to control load handling with precision.

- Woodworking In saws and planers, these cylinders ensure steady downfeed rates, producing clean cuts without damaging the wood.

- Metalworking CNC machining centers utilize hydraulic downfeed control for drilling and milling operations, allowing for high accuracy in metal shaping.

- Mining These cylinders are used in various mining applications for controlling drills and other heavy machinery that require precise movements.

Conclusion

Hydraulic downfeed control cylinders are a vital element in modern industrial processes, enabling machinery to perform tasks with precision and efficiency. Their ability to handle significant force with adjustable speed makes them suitable for a myriad of applications, solidifying their importance across multiple sectors. As technology advances, we can expect even more innovative applications for hydraulic downfeed control cylinders, enhancing productivity and ensuring high-quality outcomes in manufacturing and beyond.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025