Oct . 18, 2024 21:35 Back to list

Hydraulic Cylinder Products for Optimized Downfeed Control Solutions

Understanding Hydraulic Downfeed Control Cylinder Products

Hydraulic downfeed control cylinders are crucial components in various industrial applications, particularly in machine tools, material handling, and manufacturing processes. These devices enable precise control over the downward force exerted on materials or workpieces, ensuring efficiency and accuracy in operations. This article explores the significance, functionality, and advantages of hydraulic downfeed control cylinders.

What is a Hydraulic Downfeed Control Cylinder?

A hydraulic downfeed control cylinder is a type of actuator that utilizes hydraulic pressure to control the downward movement of a piston. This movement is typically utilized in applications where precise force and speed control are required. The cylinder is connected to a hydraulic pump, which provides the necessary fluid power to operate the system. Through a series of valves and controls, operators can regulate the flow of hydraulic fluid, thereby controlling the extension and retraction of the piston.

Applications of Hydraulic Downfeed Control Cylinders

These cylinders are widely employed in various industries, including metalworking, woodworking, and plastics manufacturing. For instance, in metal cutting processes like milling and drilling, hydraulic downfeed control cylinders provide a steady and adjustable force that improves cutting efficiency and prolongs tool life. Similarly, in woodworking, these cylinders ensure that saw blades and cutters operate with the correct feed rate, minimizing material waste and enhancing product quality.

Benefits of Using Hydraulic Downfeed Control Cylinders

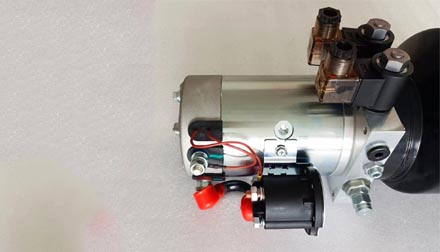

hydraulic downfeed control cylinder products

1. Precision Control One of the primary advantages of hydraulic downfeed control cylinders is their ability to deliver precise control over force and speed. This precision is essential in applications where dimensions and tolerances are critical.

2. Enhanced Productivity By enabling faster and more reliable operations, these cylinders can help increase overall productivity. Automatic adjustments to the downfeed rate allow for quicker cycle times without sacrificing quality.

3. Durability and Reliability Hydraulic systems are known for their robust nature. Hydraulic downfeed control cylinders are designed to withstand heavy loads and are less prone to wear and tear compared to mechanical counterparts.

4. Flexibility These cylinders can be easily integrated into existing systems, offering flexibility in various machinery setups. They can adapt to different operational requirements, making them suitable for diverse applications.

5. Safety Features Many hydraulic downfeed control cylinders come equipped with safety features, such as pressure relief valves, to prevent overload conditions, ensuring safe operation under various conditions.

Conclusion

In conclusion, hydraulic downfeed control cylinder products play a vital role in enhancing the efficiency and precision of industrial operations. With their ability to provide controlled and reliable force, these cylinders improve productivity and ensure quality across multiple sectors. As industries continue to adopt advanced automation and efficiency techniques, the importance of hydraulic downfeed control cylinders will only grow, making them indispensable in the modern manufacturing landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025