Dec . 10, 2024 23:59 Back to list

Hydraulic Damping Cylinders for Enhanced Performance and Reliability in Various Applications

Understanding Hydraulic Damping Cylinders A Comprehensive Overview

Hydraulic damping cylinders are essential components used in various industrial applications to control motion and absorb energy. They play a crucial role in providing stability, reducing vibrations, and preventing shock loads in a wide range of machinery and systems. To appreciate the significance of hydraulic damping cylinders, it’s important to delve into their functionality, design considerations, applications, and the advantages they offer.

What is a Hydraulic Damping Cylinder?

A hydraulic damping cylinder is a device that utilizes hydraulic fluid to dampen the motion of an object and manage the forces exerted during operation. This technology generally involves a piston within a cylinder, where fluid is displaced as the piston moves. The resistance offered by the fluid generates the damping effect, which smoothens the operation and minimizes the impact of sudden movements or shocks.

How Do Hydraulic Damping Cylinders Work?

The functioning of a hydraulic damping cylinder is based on the principles of fluid dynamics and controlled resistance. When an external force acts on the system, the piston moves, and hydraulic fluid flows through orifices or valves designed to regulate the flow rate. This controlled flow determines the level of damping experienced by the system. Depending on the system design, it may feature adjustable damping rates, allowing for customization according to specific operational needs.

Key Design Considerations

When designing hydraulic damping cylinders, several factors must be considered to ensure optimal performance. These include

1. Size and Capacity The cylinder must be sized appropriately to handle the expected load and pressure conditions. This involves calculating the area of the piston and the required stroke length.

2. Damping Characteristics Designers can choose between various damping properties, such as linear or non-linear damping. The choice affects how the cylinder responds to varying rates of motion.

3. Fluid Compatibility The hydraulic fluid must be compatible with the materials used in the cylinder to prevent degradation and ensure longevity.

4. Operating Conditions Environmental conditions, such as temperature, humidity, and potential exposure to contaminants, must be considered to enhance the durability of the cylinder.

5. Mounting Options The design should accommodate the specific mounting requirements of the application to ensure that the hydraulic cylinder performs effectively within its intended environment.

Applications of Hydraulic Damping Cylinders

Hydraulic damping cylinders find applications across numerous industries, including

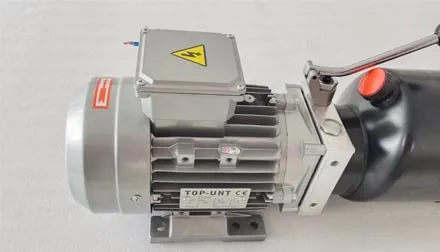

hydraulic damping cylinder product

- Automotive Used in vehicle suspension systems, hydraulic damping cylinders improve ride quality by absorbing shocks and vibrations from the road

.- Construction In heavy machinery, these cylinders provide stability and control during operation, reducing the risk of accidents and improving operator comfort.

- Aerospace Hydraulic damping is critical in aircraft landing gear systems to manage impact loads during touchdown.

- Marine Damping cylinders are used in ship stabilizers to counteract the rolling motion caused by waves, enhancing comfort and safety on board.

- Industrial Machinery Many manufacturing processes use hydraulic damping systems to minimize vibration and extend the lifespan of equipment.

Advantages of Hydraulic Damping Cylinders

The integration of hydraulic damping cylinders offers several benefits

1. Enhanced Stability By absorbing shocks and dampening vibrations, these cylinders provide a stable operating environment, which is crucial for both safety and efficiency.

2. Customizability Adjustable damping rates allow for tailored solutions that can be modified based on specific operational requirements.

3. Reduced Wear and Tear By minimizing sudden impacts and movements, hydraulic damping cylinders extend the lifespan of connected machinery and reduce maintenance costs.

4. Improved Performance With better control over motion, hydraulic dampers contribute to higher efficiency and smoother operations.

5. Versatility Their wide range of applications makes hydraulic damping cylinders valuable in various fields, showcasing their adaptability.

Conclusion

Hydraulic damping cylinders are indispensable tools in modern engineering, offering effective solutions for motion control and energy absorption. With a robust design tailored to meet the demands of various applications, these cylinders enhance the performance, safety, and durability of machinery across multiple industries. As technology continues to evolve, advancements in hydraulic damping systems will likely lead to even more efficient and effective solutions in the future, underscoring their importance in both existing and emerging applications.

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic|Heavy-Duty Lifting,Custom Hydraulic Solutions

NewsJul.30,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Precision Engineering&Industrial Lifting Solutions

NewsJul.30,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | High-Strength Hydraulic Components

NewsJul.30,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Hydraulic Solutions, Customization, Precision Engineering

NewsJul.30,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan Hydraulic Machinery Co., Ltd.|Heavy-Duty Hydraulic Cylinder&Customization Options

NewsJul.30,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsJul.30,2025