Nov . 17, 2024 10:52 Back to list

Hydraulic Dampers Manufacturing and Supply for High-Quality Cylinder Solutions

Understanding Hydraulic Damper Cylinder Factories

Hydraulic damper cylinders play a crucial role in various industrial applications, providing precise control over motion and reducing vibrations. These essential components are commonly used in automotive, aerospace, construction, and manufacturing industries. With the increasing demand for efficient and reliable hydraulic systems, the importance of hydraulic damper cylinder factories has grown significantly.

A hydraulic damper operates by using fluid dynamics to absorb shocks and impacts, enabling smoother operation in machinery and vehicles. The manufacturing process of hydraulic dampers involves several key stages, starting from design and material selection through to production and quality control. Factories specializing in hydraulic damper cylinders employ advanced technologies and skilled personnel to ensure the production of high-quality products.

The first step in the manufacturing process is the design phase, which involves creating detailed specifications based on the intended application of the damper. Engineers utilize computer-aided design (CAD) software to model the cylinder, ensuring that all components function harmoniously under varying conditions. Material selection is also critical; manufacturers often choose durable materials such as aluminum or high-strength steel to withstand high pressure and provide longevity.

After the design is finalized, the manufacturing process begins with fabricating the cylinder components. This stage includes cutting, machining, and welding various parts to create a cohesive unit. Hydraulic damper cylinder factories often incorporate CNC (Computer Numerical Control) machines to ensure precision in the production process. This technology allows for higher accuracy and repeatability, resulting in a better-quality product.

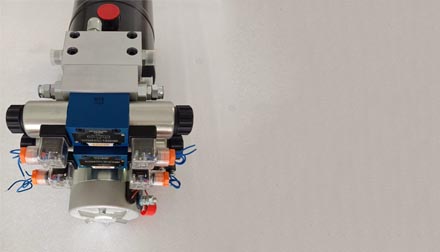

hydraulic damper cylinder factory

Once the components are assembled, the hydraulic damper undergoes rigorous testing. Factories implement various testing methods, including pressure tests and endurance tests, to assure that the damper meets industry standards for safety and performance. This quality control phase is essential, as it helps identify any defects or inconsistencies that could affect the damper's functionality.

In addition to manufacturing, many hydraulic damper cylinder factories offer customization options to meet specific client needs. This flexibility allows businesses to order dampers that are tailored to their equipment and operational requirements. As industries continue to innovate and evolve, the demand for customized hydraulic solutions will likely increase.

Moreover, sustainability is becoming a significant focus in manufacturing practices. Many factories are adopting eco-friendly initiatives, such as reducing waste and utilizing recyclable materials, to minimize their environmental impact. This shift not only benefits the planet but can also enhance a factory's reputation in an increasingly eco-conscious market.

In conclusion, hydraulic damper cylinder factories play an essential role in producing vital components for various industries. Through a combination of advanced technology, skilled craftsmanship, and a commitment to quality, these factories contribute to safer and more efficient machinery, ultimately driving innovation and progress in engineering and manufacturing.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025