Dec . 10, 2024 10:52 Back to list

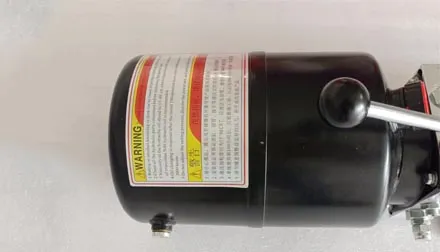

hydraulic cylinder supplier factory

The Importance of Choosing the Right Hydraulic Cylinder Supplier Factory

Hydraulic cylinders play a crucial role in various industrial applications, providing the necessary force and motion to drive machinery and equipment. As such, the choice of a reliable hydraulic cylinder supplier factory is paramount for the success of any project that utilizes hydraulic systems. This article explores the significance of selecting the right supplier, the qualities to look for, and how it can impact operational efficiency and overall project success.

Understanding Hydraulic Cylinders

Hydraulic cylinders are mechanical actuators that convert hydraulic energy into linear motion. These devices are integral to many systems, including construction equipment, manufacturing machinery, and automotive processes. Given their critical function, the reliability, performance, and longevity of hydraulic cylinders directly affect the productivity and safety of operations.

The Role of a Supplier Factory

A hydraulic cylinder supplier factory is responsible for the design, manufacturing, and distribution of these essential components. Selecting a factory that prioritizes quality control, advanced technology, and experienced personnel will ensure that the hydraulic cylinders meet the specific needs of your application. Here are several reasons why choosing the right supplier matters

1. Quality Assurance High-quality hydraulic cylinders are manufactured using durable materials and undergo stringent testing. A reputable supplier will have quality assurance processes in place to test their products for any defects, ensuring they meet industry standards and specifications.

2. Customization Different applications require different types and sizes of hydraulic cylinders. A good supplier factory should offer customization options, allowing clients to specify the dimensions, materials, and features of the cylinders to meet their unique needs.

3. Technological Advancements The hydraulic industry is constantly evolving with new technologies. A forward-thinking supplier factory invests in modern manufacturing techniques, ensuring that their products are efficient and reliable. This can include the use of computer-aided design (CAD) systems, automated machining, and advanced testing equipment.

4. Experience and Expertise An experienced supplier is often better equipped to understand customer needs and provide valuable advice on cylinder selection, installation, and maintenance. They should have a knowledgeable sales team and engineers who can assist clients in making informed decisions.

hydraulic cylinder supplier factory

5. After-Sales Support A reliable supplier factory will offer comprehensive after-sales support. This can range from installation assistance to maintenance services and repairs. A responsive support team can help minimize downtime and ensure that hydraulic systems operate efficiently.

Finding the Right Supplier

When searching for a hydraulic cylinder supplier factory, consider the following steps

- Research Conduct thorough research online to find suppliers with a strong reputation. Look for reviews, testimonials, and case studies from other customers.

- Certifications Check if the factory holds industry certifications, such as ISO 9001, which indicates adherence to quality management standards.

- Visit the Facility If possible, visit the manufacturer’s facility to evaluate their production processes and quality control measures. This firsthand experience can give you a better understanding of their capabilities.

- Request Samples Before placing a large order, request samples to assess the quality and performance of their products.

- Evaluate Communication Good communication is essential for a successful supplier relationship. Assess how responsive and helpful the supplier is during your initial interactions.

Conclusion

The selection of a hydraulic cylinder supplier factory is a decision that has far-reaching implications for your operations. By prioritizing quality, customization, technological advancements, experience, and after-sales support, businesses can find suppliers that not only meet their needs but also enhance operational efficiency and reliability. Investing time in choosing the right supplier pays off in the long run, leading to improved productivity, reduced downtime, and successful project outcomes.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025