Sep . 28, 2024 02:21 Back to list

Hydraulic Cylinder Seal Kits for Optimal Performance and Durability in Heavy Equipment

Understanding Hydraulic Cylinder Seal Kits Essential Components for Efficient Functioning

Hydraulic systems are pivotal in today's industrial landscape, powering machinery and equipment across various applications. At the heart of these systems lies the hydraulic cylinder, an essential component responsible for converting hydraulic energy into mechanical force. However, the efficiency and longevity of hydraulic cylinders largely depend on the integrity of their seal kits. In this article, we will explore the importance of hydraulic cylinder seal kits, their components, and their role in maintaining optimal hydraulic performance.

What are Hydraulic Cylinder Seal Kits?

Hydraulic cylinder seal kits are essential assemblies designed to prevent hydraulic fluid from leaking out of the cylinder while simultaneously protecting the internal components from contamination. These kits typically include a variety of seals made from different materials, each serving a specific purpose in the hydraulic system. Common types of seals found in these kits include piston seals, rod seals, wipers, and backup rings.

Key Components of Hydraulic Cylinder Seal Kits

1. Piston Seals These seals create a tight seal between the piston and the cylinder wall, ensuring that hydraulic fluid is effectively transferred to generate force. Piston seals must withstand high pressure and considerable wear, making material selection crucial.

2. Rod Seals Similar to piston seals, rod seals are responsible for sealing the area where the piston rod exits the cylinder. They prevent fluid leakage and maintain system pressure, which is vital for the smooth operation of hydraulic machinery.

3. Wipers Often referred to as scrapers, wipers play a crucial role in preventing dirt, dust, and other contaminants from entering the hydraulic cylinder. By keeping the rod clean, wipers enhance the lifespan of the seals and the cylinder itself.

4. Backup Rings These rings provide additional support to the primary seals, preventing them from extruding under high-pressure conditions. They are typically made from harder materials that help maintain the shape and functionality of the seals.

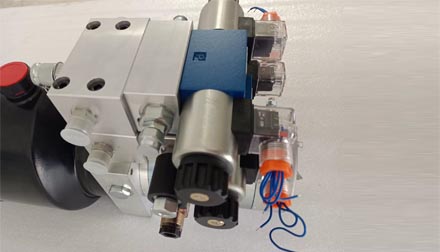

hydraulic cylinder seals kits products

Importance of Proper Seal Kits

The importance of using the right hydraulic cylinder seal kits cannot be overstated. Inadequate sealing can lead to various issues, including reduced efficiency, increased wear and tear on components, and even catastrophic system failures. Here are some reasons why investing in high-quality seal kits is essential

- Preventing Leakage High-quality seals ensure that hydraulic fluid remains contained within the cylinder, minimizing wastage and preventing harmful spills. This not only saves costs but also protects the environment from potential contamination.

- Enhancing Efficiency Proper sealing allows hydraulic systems to operate at peak efficiency. When seals are compromised, the system may require more power to maintain performance, leading to increased energy consumption and operational costs.

- Extending Equipment Life Regular maintenance, including seal replacement, can significantly extend the lifespan of hydraulic cylinders and related machinery. By preventing contamination and excessive wear, quality seal kits help to maintain the integrity of the entire hydraulic system.

- Improving Safety Leaking hydraulic fluids can pose serious safety risks in industrial settings. By ensuring that seals are functioning correctly, the likelihood of accidents due to hydraulic failures can be greatly reduced.

Conclusion

In summary, hydraulic cylinder seal kits are crucial components that directly impact the performance, efficiency, and safety of hydraulic systems. Selecting the right seal kit and maintaining it properly can lead to significant long-term benefits, including reduced downtime and maintenance costs. Industries relying on hydraulic machinery must prioritize the use of high-quality seal kits to ensure the optimal functioning of their equipment.

-

China Carbon Fiber Hydraulic Cylinder Light & Durable

NewsJun.05,2025

-

Premium T5 Hydraulic Slave Cylinder Factories Quality Production

NewsJun.05,2025

-

Wingspan Power Unit Company Efficient Power Solutions for Industry

NewsJun.04,2025

-

High-Performance Wingspan Power Unit Products Energy Solutions

NewsJun.04,2025

-

Premium Curved Hydraulic Cylinders Durability & Precision

NewsJun.04,2025

-

Heavy-Duty 3x8 Hydraulic Cylinder Premium Industrial Solution

NewsJun.04,2025