Nov . 04, 2024 09:37 Back to list

hydraulic cylinder rod ends factory

Hydraulic Cylinder Rod Ends An Overview of Manufacturing and Applications

Hydraulic cylinder rod ends play a vital role in the functioning of hydraulic systems. These components are essential in transferring force and motion, making them critical in various machinery and applications. The manufacturing of hydraulic cylinder rod ends requires precision engineering and dedicated facilities, ensuring reliability and performance under pressure.

What are Hydraulic Cylinder Rod Ends?

Hydraulic cylinder rod ends are connection points that link the hydraulic cylinder with other mechanical elements. They typically consist of a spherical bearing design, allowing for a degree of angular movement and flexibility within the hydraulic system. This design minimizes friction and enables smooth operation, which is crucial in dynamic applications where the rod may need to pivot or rotate.

Manufacturing Process

Manufacturing hydraulic cylinder rod ends begins with selecting high-quality materials. Common materials used include carbon steel, stainless steel, and sometimes aluminum alloys, depending on the application requirements. Precision machining is employed to shape these materials into the desired configurations.

The manufacturing process typically involves several key steps

1. Casting and Forging Raw materials are either cast or forged into rough shapes that approximate the final product. This process enhances the material's strength and durability.

2. Machining Using CNC machines, the rough shapes are meticulously cut and finished to meet exact specifications. This includes drilling holes for mounting and creating ball sockets for smooth motion.

3. Heat Treatment To improve the material properties, heat treatment processes such as tempering and hardening are used. This process helps to increase wear resistance and strength.

4. Surface Finishing The final machining is followed by surface treatments such as galvanizing or coating to prevent corrosion, which is especially important in hydraulic applications.

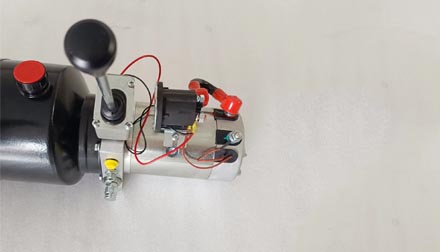

hydraulic cylinder rod ends factory

5. Quality Control Every batch of hydraulic cylinder rod ends undergoes rigorous testing to ensure they meet industry standards and specifications. This includes dimensional checks, load testing, and inspections for surface defects.

Applications

Hydraulic cylinder rod ends are utilized across various industries due to their versatility and durability. Some common applications include

- Construction Equipment Hydraulic systems are integral to the operation of excavators, bulldozers, and cranes, where rod ends facilitate movement and power transfer.

- Agricultural Machinery Rod ends are found in tractors and harvesters, enabling the operation of various hydraulic implements.

- Automotive Industry In vehicles, hydraulic systems are critical for braking and steering functions, where rod ends create crucial linkages between components.

- Marine Applications Boats and ships utilize hydraulic systems for steering and control, making reliable rod ends essential for safety and performance.

- Industrial Machinery Many manufacturing and assembly machines rely on hydraulic cylinders for precise movements, with rod ends ensuring smooth operation.

Conclusion

The manufacturing of hydraulic cylinder rod ends is a sophisticated process that combines material science, engineering precision, and quality assurance. These components are fundamental to the operation of hydraulic systems across a myriad of industries, enhancing efficiency and safety. As technology advances, the design and materials used for hydraulic cylinder rod ends will continue to evolve, driving improvements in performance and reliability. Thus, investing in high-quality rod ends is paramount for any business that relies on hydraulic machinery.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025