Oct . 07, 2024 14:28 Back to list

hydraulic cylinder price factory

Understanding Hydraulic Cylinder Prices The Factors Behind the Cost

Hydraulic cylinders are critical components in various industrial applications, including manufacturing, construction, and automotive industries. They convert hydraulic energy into mechanical force, enabling heavy machinery to perform tasks such as lifting, pushing, pulling, and tilting with remarkable efficiency. However, when considering the purchase of hydraulic cylinders, one of the most pressing questions businesses face is what influences the price of these essential devices?

1. Manufacturing Quality and Standards

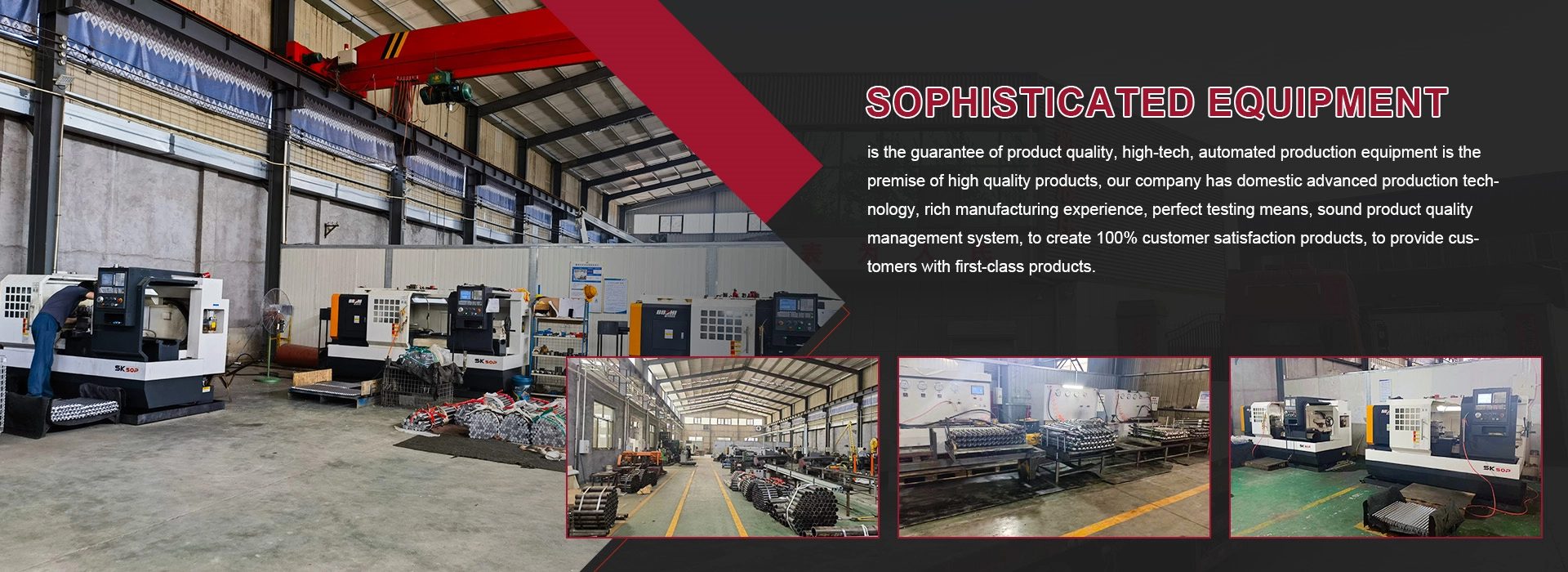

One of the primary factors affecting hydraulic cylinder pricing is the quality of manufacturing. High-quality hydraulic cylinders are manufactured to strict industry standards, ensuring reliability and longevity. Manufacturers that adhere to international standards, such as ISO 9001, typically invest in premium materials and advanced production techniques. This results in hydraulic cylinders that can withstand high pressure and harsh working conditions, justifying a higher price point. In contrast, lower-quality cylinders may be cheaper but can lead to decreased performance and more frequent failures, ultimately costing more in terms of repairs and downtime.

2. Material Selection

The materials used to construct hydraulic cylinders play a significant role in determining their cost. Common materials include steel, aluminum, and composite materials, each with its unique properties and price points. For instance, steel cylinders are often more expensive than aluminum ones due to their ability to handle higher pressures and resist wear. However, the choice of material also depends on specific application requirements; thus, manufacturers may offer customized solutions that can affect pricing. Companies must assess their operational needs and choose hydraulics that balance performance and budget.

The size of a hydraulic cylinder directly impacts its price. Larger cylinders, designed to handle greater loads, inherently require more material and processing time, leading to increased costs. Furthermore, specifications such as stroke length, bore size, and rod diameter must be considered. Customized cylinders, built to meet particular operational demands, usually come with a premium price. For businesses requiring standard sizes, off-the-shelf options may provide cost savings, but it is essential to ensure these meet the specific performance criteria.

hydraulic cylinder price factory

4. Brand Reputation

Well-established brands in the hydraulic cylinder market often command higher prices than less-known manufacturers. This is due to a combination of factors, including perceived reliability, warranty offerings, and customer service. Many businesses prefer to invest in trusted brands, believing that the assurance of quality and support warrants the additional cost. However, it is essential to conduct thorough research and compare multiple brands to ensure that the product's performance aligns with its price.

5. Order Volume and Customization

Pricing may also vary based on the order volume. Many manufacturers offer discounts for bulk purchases, enabling businesses to save significantly when procuring numerous hydraulic cylinders at once. Additionally, customized solutions tailored to specific applications may lead to higher individual cylinder costs due to the design and engineering efforts involved. Thus, companies should evaluate whether standard models meet their needs or if customization is necessary and justifiable.

6. Geographic Location and Logistics

Finally, geographic factors and logistics come into play when determining hydraulic cylinder prices. Costs may vary significantly based on the manufacturer's location, availability of materials, and shipping expenses. International imports can incur additional tariffs and duties, further influencing the final price. Consequently, businesses are often encouraged to source cylinders locally or consider regional manufacturers to mitigate high shipping costs.

Conclusion

In summary, numerous factors influence the price of hydraulic cylinders, including manufacturing quality, materials, size, brand reputation, order volume, and geographic location. Businesses must take the time to assess their specific needs, conduct comparative research, and evaluate long-term value against initial costs. Choosing the right hydraulic cylinder is not merely a matter of price but involves understanding the balance between quality, performance, and overall operational efficiency. By making informed decisions, companies can ensure they invest wisely in hydraulic systems that meet their demands without compromising on quality or performance.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025