Nov . 04, 2024 22:00 Back to list

hydraulic cylinder nearby product

The Importance of Hydraulic Cylinders in Modern Engineering

Hydraulic cylinders are a vital component in various industrial applications, serving as the backbone of numerous machines and systems that require efficient force generation and motion control. As industries evolve, so too does the technology surrounding hydraulic systems, with innovations leading to improvements in performance, safety, and efficiency. Understanding the significance of hydraulic cylinders, especially their nearby products, is essential for engineers, manufacturers, and technicians alike.

At its core, a hydraulic cylinder converts hydraulic energy into mechanical energy. This transformation allows the hydraulic cylinder to produce linear motion, which is often required in applications ranging from construction equipment to aerospace machinery. The principles of hydraulics are rooted in Pascal's law, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This fundamental principle allows hydraulic cylinders to generate substantial amounts of force with relatively minimal input effort.

The Importance of Hydraulic Cylinders in Modern Engineering

In addition to construction, hydraulic cylinders find applications in manufacturing processes. They are often used in presses for metal forming, providing the necessary force to shape materials under controlled conditions. The use of hydraulic presses enhances production efficiency and ensures consistent quality in manufactured components. Furthermore, hydraulic systems are also integral in automotive industries, where they are used for everything from assembly line automation to braking systems.

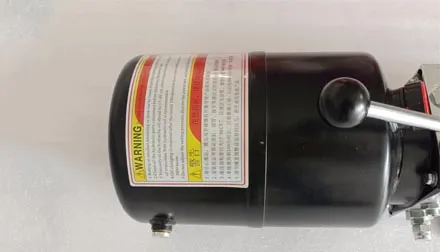

hydraulic cylinder nearby product

The products adjacent to hydraulic cylinders—such as hydraulic pumps, hoses, and valves—play equally crucial roles in the overall system performance. Hydraulic pumps are responsible for generating the flow of hydraulic fluid needed for the cylinders to operate. Ensuring that the right type of hydraulic fluid is used, along with the appropriate hoses and connectors, is essential for maintaining the integrity and efficiency of the hydraulic system. Seamless integration of these elements leads to improved responsiveness and reliability, which are critical in high-stakes environments like manufacturing and heavy industry.

Moreover, advancements in hydraulic technology have led to the development of smart hydraulic systems equipped with sensors and controllers. These modern systems can monitor performance in real-time, allowing for predictive maintenance and reduced downtime. The integration of IoT (Internet of Things) capabilities with hydraulic systems is paving the way for more efficient industries that prioritize sustainability and reduced operational costs.

Safety is another paramount concern when dealing with hydraulic systems. High pressures can pose significant risks, and awareness of potential hazards is vital. Proper maintenance of hydraulic cylinders and their surrounding components is essential to prevent leaks, bursts, or malfunctions. Training personnel to understand and operate these systems safely is equally important to ensure a secure workplace.

In conclusion, hydraulic cylinders and their nearby products are indispensable in modern engineering and industrial applications. Their ability to provide powerful, efficient motion makes them a preferred choice across various sectors. As technology continues to advance, the future of hydraulic systems looks promising, with innovations paving the way for enhanced performance, safety, and environmental responsibility. Understanding the complexities and interdependencies of hydraulic systems is crucial for anyone involved in engineering or manufacturing, as they remain an essential element of mechanical power generation.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025