Nov . 08, 2024 02:19 Back to list

Hydraulic Cylinder Manufacturing Companies and Their Factory Production Processes

The Role of Hydraulic Cylinder Manufacturers in Modern Industry

Hydraulic cylinders are key components in a vast array of industrial applications, serving as the muscle behind many machines and systems. As an essential element of hydraulic systems, these cylinders convert hydraulic energy into mechanical force. The importance of hydraulic cylinder manufacturers cannot be overstated, as they provide the critical products that enable machinery to function efficiently and reliably.

Understanding Hydraulic Cylinders

Hydraulic cylinders are devices that use pressurized fluid to produce motion. They come in various sizes and configurations, depending on the specific application they are designed for. Common types include single-acting cylinders, double-acting cylinders, and telescopic cylinders, each serving unique purposes across different industries. These cylinders are used in construction equipment, manufacturing machinery, automotive applications, and in many other fields, showcasing their versatility.

The Manufacturing Process

The manufacturing of hydraulic cylinders involves several critical steps, from design and selection of materials to testing and quality assurance. A hydraulic cylinder manufacturer typically begins by analyzing customer specifications to create a tailored design that meets the specific requirements of the intended application. Advanced computer-aided design (CAD) software is often employed during this phase to ensure precision.

Once the design is finalized, manufacturers select appropriate materials that can withstand high pressures and harsh environments. Common materials include high-strength steel, aluminum, and specialized alloys. After material selection, the manufacturing process involves several techniques, including machining, welding, and assembly. Precision machining is crucial, as components must fit together perfectly to prevent leaks and ensure efficient operation.

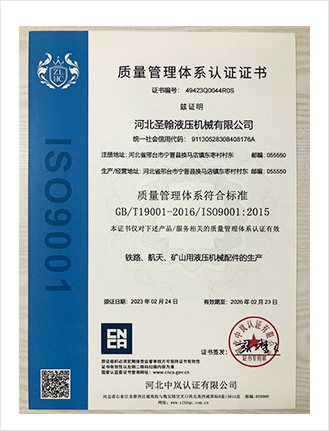

Quality control is paramount throughout the manufacturing process. Manufacturers employ rigorous testing protocols to ensure that each hydraulic cylinder meets industry standards and customer expectations. This may include pressure testing, dimensional inspections, and performance evaluations. By adhering to strict quality assurance practices, manufacturers can guarantee the reliability and longevity of their products.

hydraulic cylinder manufactures factories

The Importance of Innovation

In the competitive landscape of hydraulic cylinder manufacturing, innovation plays a vital role. As industries evolve and demand for more efficient and reliable machinery increases, manufacturers are continually seeking ways to improve their products. This includes advancements in materials, design techniques, and manufacturing processes.

For example, the use of composite materials has gained traction in recent years, enabling manufacturers to create lighter and more durable cylinders. Additionally, advancements in sealing technology have led to improved performance in extreme conditions, minimizing the risk of leaks and enhancing the lifespan of hydraulic systems. Manufacturers that invest in research and development are better equipped to adapt to changing industry needs and maintain a competitive edge.

Global Reach of Hydraulic Cylinder Manufacturers

Hydraulic cylinder manufacturers operate on a global scale, supplying products to various industries around the world. Key players in this market are often situated in industrial hubs where there is a concentration of manufacturing activity. Countries like the United States, Germany, Japan, and China are recognized for their robust hydraulic cylinder manufacturing sectors.

International trade and globalization have further expanded the reach of these manufacturers. By engaging in export activities, they can access new markets and customer bases, driving growth and innovation. Customers seeking hydraulic cylinders can benefit from the expertise and product offerings of manufacturers worldwide, ensuring they find the right solutions for their needs.

Conclusion

In conclusion, hydraulic cylinder manufacturers play a crucial role in supporting the machinery and systems that power modern industry. Through precision engineering, rigorous quality control, and continuous innovation, these manufacturers provide reliable products that enhance operational efficiency across a variety of applications. As industries continue to evolve, the importance of hydraulic cylinder manufacturers will only increase, highlighting the significance of their contributions to the industrial landscape. The future of hydraulic technology looks promising, driven by the commitment of manufacturers to deliver cutting-edge solutions that meet the ever-growing demands of the market.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025