Oct . 18, 2024 13:10 Back to list

Hydraulic Cylinder Leakage Solutions and Products to Prevent Fluid Loss

Understanding Hydraulic Cylinder Leaking Products

Hydraulic systems are integral to a wide range of industrial applications, providing the necessary force to perform mechanical tasks efficiently. Among the critical components of these systems, hydraulic cylinders play a pivotal role. However, one prevalent issue that operators face is hydraulic cylinder leaking, which can lead to significant operational inefficiencies and safety concerns. In this article, we will explore the causes, effects, and solutions related to hydraulic cylinder leaks, as well as some of the products available for managing these problems.

Causes of Hydraulic Cylinder Leaks

Hydraulic cylinder leaks can arise from various factors, and understanding these causes is essential for effective prevention and management. Common causes include

1. Worn Seals Over time, the seals in hydraulic cylinders can wear out due to repeated cycling and exposure to harsh chemicals. Once these seals are compromised, hydraulic fluid can escape, leading to leaks.

2. Poor Installation Improper installation of hydraulic cylinders can create misalignment and undue stress on the seals and components, resulting in leaks.

3. Contaminated Fluid The presence of dirt, debris, or abrasive particles in the hydraulic fluid can cause wear and tear on seals, leading to leaks. Maintaining fluid cleanliness is essential for the longevity of hydraulic systems.

4. Corrosion and Damage Environmental factors such as moisture and corrosive chemicals can cause corrosion of metal parts within the hydraulic cylinder, further contributing to leakage.

5. Pressure Surges Sudden pressure spikes can exceed the design limits of seals and components, causing them to rupture and create leaks.

Effects of Hydraulic Cylinder Leaks

The consequences of hydraulic cylinder leaks can be quite severe for both operational efficiency and safety

1. Reduced Performance Leaks reduce the efficiency of hydraulic systems, leading to lower operational performance. This can slow down production processes and affect overall machine productivity.

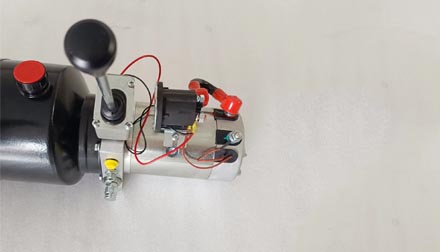

hydraulic cylinder leaking products

2. Increased Downtime When leaks occur, equipment may need to be shut down for repairs or replacements, resulting in costly downtime.

3. Environmental Concerns Hydraulic fluid is often environmentally hazardous. Leaks can lead to spills, which can harm the environment and necessitate expensive cleanup efforts.

4. Safety Hazards Leaking hydraulic fluid poses a safety risk to operators, as it can lead to slippery surfaces and increase the chance of accidents.

Solutions for Managing Leaks

Fortunately, there are numerous products and solutions available to manage and prevent hydraulic cylinder leaks

1. Sealing Solutions There are various seal kits and replacement seals designed specifically for hydraulic cylinders. These products are engineered to withstand high pressures and temperatures, ensuring a tight seal and reducing the risk of leaks.

2. Fluid Spin Filters Installing fluid spin filters can help maintain the cleanliness of hydraulic fluid, removing contaminants that may lead to the wear of seals and other components.

3. Leak Detection Systems Implementing leak detection systems can help identify leaks early on, allowing for prompt actions to be taken before significant damage or fluid loss occurs.

4. Sealant Products Chemical sealants can be applied to leaking joints or threads as a temporary solution to stop leaks until a more permanent fix can be made.

5. Regular Maintenance Establishing a routine maintenance schedule can help identify potential issues before they become severe. Regular inspections, fluid analysis, and timely seal replacements can extend the life of hydraulic systems and prevent leaks.

Conclusion

In conclusion, hydraulic cylinder leaking is a common issue that can pose significant challenges for industries relying on hydraulic systems. By understanding the causes and effects of leaks, as well as exploring available products and solutions, operators can effectively manage and mitigate these problems. Investing in quality sealing solutions, maintaining hydraulic fluid cleanliness, and implementing regular maintenance practices are critical steps in ensuring the efficiency and safety of hydraulic systems. This preparedness not only enhances performance but also contributes to the longevity of the equipment and the operator's peace of mind.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025