Nov . 17, 2024 23:28 Back to list

Hydraulic Cylinder Applications in Modern Industrial Manufacturing Environments and Factories

Hydraulic Cylinders in Industrial Factories A Backbone of Modern Machinery

Hydraulic cylinders play a crucial role in the functioning of various industrial factories, serving as essential components in numerous machinery systems. Their design and application are pivotal in enabling efficient operations across a wide range of industries, from manufacturing to construction. This article explores the significance of hydraulic cylinders, their operational principles, and their impact on industrial productivity.

Hydraulic Cylinders in Industrial Factories A Backbone of Modern Machinery

One of the primary advantages of hydraulic cylinders is their ability to generate immense power in a compact size. Unlike mechanical systems that may require large gears and levers to transfer force, hydraulic systems can produce the same amount of force from a much smaller footprint. This not only saves space in factories but also allows for more flexible designs in machinery. Industries such as agriculture, automotive, and aerospace heavily rely on hydraulic cylinders to operate machinery such as forklifts, excavators, and assembly line robots.

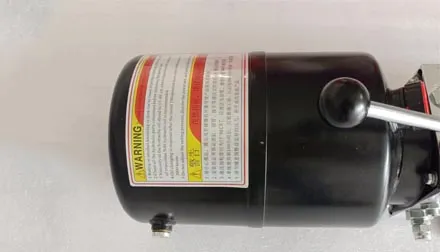

hydraulic cylinder industrial factories

Moreover, hydraulic cylinders are renowned for their ability to handle heavy loads with remarkable efficiency and stability. Their design typically includes robust materials that allow them to withstand high pressures and endure tough operating conditions. This durability ensures that machinery remains operational over extended periods, reducing downtime and maintenance costs, which are critical factors in maintaining productivity in industrial environments.

In addition to their mechanical advantages, hydraulic cylinders also offer precision in their operations. Whether it’s controlling the speed of movement or adjusting the position of heavy machinery, hydraulic systems can be finely tuned to meet specific requirements. This level of control is imperative in applications where safety and accuracy are paramount, such as in the assembly of intricate components or the lifting of heavy structures.

Despite their many benefits, it’s essential for industrial factories to implement regular maintenance and inspections of hydraulic systems. Over time, seals may wear out, fluid may leak, and components can suffer from fatigue. Proactive maintenance ensures that hydraulic cylinders operate at peak performance, helping to avoid costly failures and ensuring worker safety.

In conclusion, hydraulic cylinders are indispensable tools in industrial factories, enabling efficient operation, space-saving designs, and robust performance. Their ability to convert hydraulic energy into mechanical work makes them fundamental to the smooth operation of modern machinery. As industries continue to evolve, the innovation in hydraulic technology will undoubtedly enhance productivity and efficiency, solidifying the hydraulic cylinder's place as an essential component within industrial applications. The combination of power, precision, and reliability makes hydraulic cylinders a backbone of industrial factory operations.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025