Nov . 08, 2024 04:15 Back to list

Hydraulic Cylinder Fluid Purging Techniques for Optimal Performance and Maintenance

The Importance of Bleeding Hydraulic Cylinders in Manufacturing

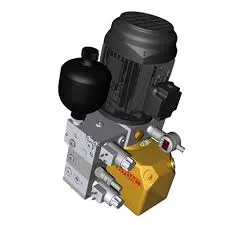

Hydraulic systems are integral components in numerous manufacturing processes, providing the necessary force to operate machinery and heavy equipment. At the heart of these systems are hydraulic cylinders, which convert hydraulic energy into mechanical energy. However, for these cylinders to function effectively, they must be properly maintained, which includes a crucial process known as bleeding. This article will explore the significance of bleeding hydraulic cylinders in a factory setting, its procedure, and its impact on the overall productivity of manufacturing operations.

The Importance of Bleeding Hydraulic Cylinders in Manufacturing

The primary reason for bleeding hydraulic cylinders is to ensure optimal cylinder performance. When air is present in the hydraulic fluid, it can lead to a phenomenon known as cavitation. This occurs when the hydraulic fluid vaporizes and forms air bubbles, which can collapse and produce shock waves that may damage the cylinder's seals and internal components. Over time, this can lead to leaks and costly repairs, thus highlighting the need for routine bleeding as part of maintenance protocols.

hydraulic cylinder bleeding factory

The procedure for bleeding hydraulic cylinders typically involves a few straightforward steps. First, the operator must ensure that the equipment is turned off and depressurized. Identifying the bleeder valve on the cylinder is essential, as this is where the air will be released. After attaching a hose to the valve to direct any escaping fluid, the operator slowly opens the bleeder valve to allow trapped air to escape. It’s important to monitor the fluid flow continuously, keeping an eye out for any signs of fluid escaping without bubbles, indicating that all air has been purged from the system. Once the air is completely released, the valve is closed securely, and the system can be returned to normal operation.

In a factory setting, the impacts of properly bleeding hydraulic cylinders can be profound. Enhanced efficiency is one of the most significant benefits, as cylinders operate at their full potential without the interference of trapped air. This translates to smoother and more consistent operation of machinery, leading to increased production rates. Additionally, regular maintenance—including bleeding cylinders—can extend the lifespan of hydraulic components, reducing downtime and maintenance costs associated with repair or replacement.

Moreover, a well-maintained hydraulic system contributes to workplace safety. Erratic movements caused by air in the system can pose risks to operators and other personnel in the manufacturing facility. By ensuring that hydraulic cylinders are free of air and functioning smoothly, factories can create a safer working environment.

In conclusion, bleeding hydraulic cylinders in a manufacturing context is not simply a maintenance task; it is a crucial process that ensures the reliability and efficiency of hydraulic systems. By preventing air entrapment, manufacturers can enhance productivity, extend the longevity of their equipment, and promote a safer workplace. As such, incorporating regular bleeding of hydraulic cylinders into maintenance schedules is essential for any factory utilizing hydraulic systems.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025