Oct . 05, 2024 14:28 Back to list

Top 5 Hydraulic Cylinder Manufacturers to Consider for Your Needs

Exploring the World of Hydraulic Cylinder Factories

Hydraulic cylinders are integral components in various industries, serving as the driving force behind many mechanical systems. These devices convert hydraulic energy into mechanical energy, enabling machinery to perform tasks with remarkable strength and precision. Across the globe, numerous factories specialize in the manufacturing of hydraulic cylinders, contributing to the growth of sectors like construction, automotive, and manufacturing. This article delves into the characteristics, processes, and innovations found in hydraulic cylinder factories.

1. Importance of Hydraulic Cylinders

Hydraulic cylinders play a crucial role in applications ranging from heavy construction equipment to manufacturing machinery. Their ability to provide linear motion and high force output makes them indispensable in tasks such as lifting, pushing, and pulling. The versatility of hydraulic cylinders allows them to be used in various equipment, including excavators, forklifts, and automated assembly lines.

2. Key Processes in Hydraulic Cylinder Manufacturing

The production of hydraulic cylinders involves several key processes. Initially, manufacturers select the appropriate raw materials, typically high-strength steel or aluminum, to ensure durability and performance. The manufacturing process often includes several stages

- Machining This stage involves cutting and shaping the materials into the required forms. Precision machining is essential to achieving the correct dimensions and tolerances that affect the cylinder's performance.

- Welding After machining, components such as the cylinder barrel and end caps are welded together

. This step demands high-quality welding techniques to maintain the integrity and leak-proof nature of the cylinder.- Surface Treatment To enhance corrosion resistance and durability, the cylinders undergo various surface treatments, such as painting, anodizing, or plating.

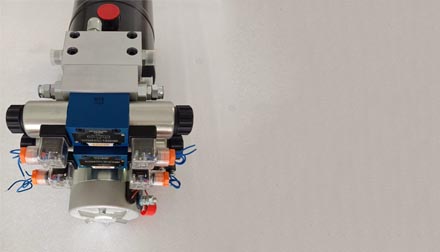

hydraulic cylinder 5 factories

- Assembly and Testing Finally, the cylinders are assembled, including the installation of piston seals and other internal components. Rigorous testing is then conducted to ensure the cylinders meet safety and quality standards. This may involve hydrostatic or pneumatic tests to check for leaks and operational efficiency.

3. Innovations in Hydraulic Cylinder Production

As technology advances, so does the manufacturing process for hydraulic cylinders. Factories are increasingly adopting automation and robotics to enhance production efficiency and consistency. Advanced computer-aided design (CAD) software allows for better design flexibility and prototyping, enabling manufacturers to create custom solutions tailored to specific client needs.

Moreover, the integration of smart technology into hydraulic systems, such as sensors and IoT connectivity, has led to the development of more intelligent hydraulic cylinders. These smart cylinders can provide real-time data on performance, enabling predictive maintenance and reducing downtime in industrial applications.

4. Environmental Considerations

In light of growing environmental concerns, hydraulic cylinder factories are also focusing on sustainability. Many manufacturers are implementing eco-friendly practices, such as reducing waste and energy consumption during the production process. The use of recyclable materials and the development of biodegradable hydraulic fluids are also on the rise.

Conclusion

Hydraulic cylinder factories are at the forefront of an essential industry, producing components that power machinery across multiple sectors. With continuous innovations and a drive towards sustainability, these factories will remain pivotal in shaping the future of hydraulic technology, enhancing productivity while minimizing their ecological footprint. As industries evolve, the hydraulic cylinder will continue to be a vital tool in powering progress and efficiency.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025