Nov . 29, 2024 10:39 Back to list

Hydraulic Air Cylinder Solutions for Enhanced Performance and Efficiency in Industrial Applications

Understanding Hydraulic Air Cylinder Products A Comprehensive Overview

Hydraulic air cylinders are pivotal components in various industrial applications that combine the principles of hydraulics and pneumatics to deliver efficient, reliable, and powerful motion control. By harnessing the advantages of both air and hydraulic fluid, these cylinders can achieve remarkable performance in demanding environments. This article delves into the functionality, advantages, applications, and considerations regarding hydraulic air cylinder products.

What Are Hydraulic Air Cylinders?

Hydraulic air cylinders are devices that convert hydraulic energy into mechanical energy through a linear motion. They typically consist of a cylinder barrel, piston, and end caps, functioning similarly to both hydraulic and pneumatic cylinders. However, the unique aspect of hydraulic air cylinders is their capability to utilize compressed air in conjunction with hydraulic fluids, enabling them to operate in scenarios where both mediums can be advantageous.

How They Work

The operation of a hydraulic air cylinder is based on the difference in pressures generated by the compression of air and the transmission of hydraulic fluid. When the valve is opened, air enters the cylinder, causing the piston to move. Simultaneously, hydraulic fluid is channeled to assist in the movement, creating a powerful and controlled stroke. The integration of both air and hydraulic fluid allows for smooth transitions between powering and holding forces, making them ideal for precise applications.

Advantages of Hydraulic Air Cylinders

1. Power and Efficiency Hydraulic air cylinders exhibit significant power capabilities, enabling them to handle heavy loads with ease. The combined use of hydraulic fluid and air results in high-efficiency motion control, ensuring that energy is effectively utilized.

2. Versatility These cylinders can be adapted for various applications, from manufacturing and assembly to robotics and material handling. Their ability to function under different environments and with varying loads makes them highly versatile.

3. Precise Control The dual operation mechanism allows for finer control of speed and force, essential for tasks that require accuracy and consistency. This feature is particularly beneficial in automated systems where precision is paramount.

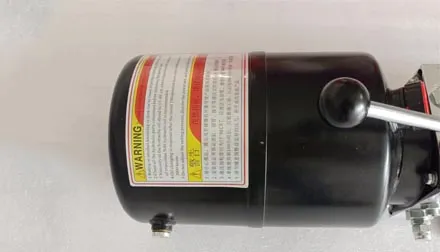

hydraulic air cylinder products

4. Reduced Risk of Contamination Unlike pure hydraulic systems that rely solely on fluid, hydraulic air cylinders can operate with less risk of contamination. The ability to leverage air reduces the chances of hydraulic fluid leaks, which can compromise operational integrity.

Applications of Hydraulic Air Cylinders

Hydraulic air cylinders find applications in various sectors

- Manufacturing Used in assembly lines for lifting, pushing, and pulling components with precise force and speed. - Automotive Industry Employed in robotic arms for tasks such as welding and painting, where precision and control are crucial. - Material Handling Ideal for loading and unloading heavy materials on conveyor belts and lifts, ensuring smooth and efficient operations. - Aerospace Utilized in adjustable wing flaps and landing gear mechanisms, where reliable actuation is critical for safety.

Considerations When Choosing Hydraulic Air Cylinders

When selecting hydraulic air cylinder products, several factors must be considered

- Load Capacity Determine the maximum load the cylinder will need to handle to choose an appropriately sized model. - Stroke Length Assess the required stroke length for the application to ensure the cylinder provides adequate range of motion. - Working Environment Consider the environmental conditions such as temperature and humidity, which can affect performance and durability. - Maintenance Evaluate the maintenance requirements to ensure the longevity and reliability of the cylinders.

Conclusion

In conclusion, hydraulic air cylinders represent an innovative intersection of hydraulic and pneumatic technologies, offering diverse capabilities for efficient motion control. With their numerous advantages, including power, versatility, and precision, these cylinders have become indispensable in various industrial applications. By understanding their mechanisms and applications, businesses can effectively integrate hydraulic air cylinders into their processes, maximizing efficiency and enhancing operational outcomes. As industries continue to evolve, hydraulic air cylinder products will remain a cornerstone in the pursuit of reliable and effective automation solutions.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025