Nov . 25, 2024 18:29 Back to list

Hydraulic Air Cylinder Solutions for Enhanced Performance and Efficiency in Industrial Applications

The Advancements of Hydraulic Air Cylinders A Comprehensive Overview

Hydraulic air cylinders have emerged as pivotal components in a wide range of industrial applications, blending the strengths of hydraulic and pneumatic systems to provide efficient and reliable actuation solutions. This article delves into the principles, applications, advantages, and recent advancements of hydraulic air cylinders, highlighting their significance in modern engineering.

Understanding Hydraulic Air Cylinders

At its core, a hydraulic air cylinder is a device that uses the energy generated from compressed air and hydraulic fluid to produce linear motion. This dual-operation system combines the rapid response of pneumatic cylinders with the high force output characteristic of hydraulic systems. The basic design of a hydraulic air cylinder typically consists of a cylinder barrel, a piston, and a rod. The interaction between air pressure and hydraulic fluid creates a versatile actuator capable of performing various tasks with precision.

Key Applications

Hydraulic air cylinders find applications across multiple industries, including manufacturing, automotive, construction, and aerospace. Their versatility makes them ideal for both light-duty and heavy-duty tasks. For instance, in the automotive sector, these cylinders are commonly used for clamping, pressing, and lifting operations, enhancing productivity and safety on assembly lines. In manufacturing, they are employed in packaging machines, conveyor systems, and robotics, where rapid and accurate movements are crucial.

In construction and heavy machinery, hydraulic air cylinders enable the operation of equipment like excavators, bulldozers, and cranes, facilitating material handling and landscape manipulation with minimal effort. Similarly, in aerospace applications, these cylinders assist in flight control systems and landing gear operations, ensuring reliability and safety during critical phases of flight.

Advantages of Hydraulic Air Cylinders

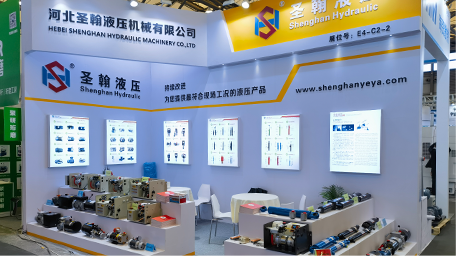

hydraulic air cylinder product

One of the primary advantages of hydraulic air cylinders is their ability to generate significant force within a compact design. This characteristic is especially beneficial in environments where space is limited and high power output is necessary. Additionally, these cylinders are capable of providing smooth and controlled motion, which is essential for tasks that require precision, such as in robotic applications.

Another notable benefit is their energy efficiency. When compared to traditional hydraulic systems, hydraulic air cylinders can operate at lower energy levels while still delivering optimal performance. This efficiency not only reduces operational costs but also contributes to more sustainable practices within industries.

Moreover, the use of hydraulic fluids and compressed air allows for rapid cycle times, significantly improving productivity. They can be easily integrated into existing systems, making them an attractive choice for industries looking to upgrade their equipment without extensive modifications.

Recent Advancements

The evolution of hydraulic air cylinders has been marked by several technological advancements aimed at enhancing their performance and reliability. Recent developments include the integration of smart technologies, such as sensors and IoT connectivity, which facilitate real-time monitoring and predictive maintenance. These innovations allow operators to track the performance of hydraulic air cylinders, reducing downtime and ensuring optimal functioning.

Additionally, manufacturers are focusing on materials that offer improved durability and resistance to wear, corrosion, and extreme temperatures. This enhancement increases the lifespan of hydraulic air cylinders and reduces maintenance requirements, contributing to greater operational efficiency.

Conclusion

Hydraulic air cylinders represent a significant advancement in actuator technology, combining the benefits of both hydraulic and pneumatic systems to meet the demands of modern industries. With their broad range of applications, efficiency, and continuous technological improvements, they play a crucial role in enhancing productivity and safety in various sectors. As industries continue to evolve, the importance of hydraulic air cylinders is likely to grow, leading to even more innovative solutions and applications in the years to come.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025