Aug . 30, 2024 08:16 Back to list

High-Quality Hydraulic Rotary Cylinders | Leading Factory Solutions

The Hydraulic Rotary Cylinder Factory A Nexus of Innovation and Efficiency

In the modern industrial landscape, hydraulic rotary cylinders play a crucial role in numerous applications, ranging from construction machinery to automated manufacturing systems

. The hydraulic rotary cylinder factory stands as a beacon of innovation and efficiency, exemplifying the technological advancements in hydraulic systems and their applications.Hydraulic rotary cylinders function by converting hydraulic energy into mechanical energy, allowing for controlled rotational movement. This mechanism is essential in various sectors, including mining, construction, and marine industries, where precision and strength are paramount. A state-of-the-art factory dedicated to the production of hydraulic rotary cylinders employs advanced engineering techniques and stringent quality control measures to ensure reliability and performance.

The manufacturing process begins with the careful selection of high-quality materials. Steel and aluminum are commonly used due to their superior strength-to-weight ratios and resistance to corrosion. Once materials are chosen, they undergo rigorous testing to meet industry standards. The factory utilizes computer-aided design (CAD) software to create precise models of the hydraulic cylinders, ensuring optimum performance and compatibility with a wide range of machinery.

Automation plays a significant role in increasing productivity within hydraulic cylinder factories. Robotic arms and automated machinery are employed for tasks such as welding, machining, and assembly, reducing human error and improving precision. Moreover, automation allows factories to operate with greater efficiency, meeting the increasing demands of various industries without compromising quality.

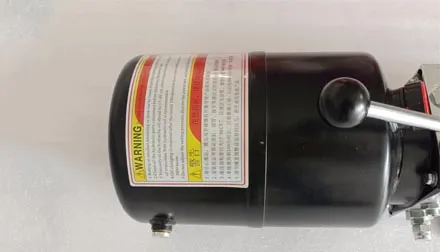

hydraulic rotary cylinder factory

Quality assurance is paramount in the production of hydraulic rotary cylinders. Each product undergoes a series of tests to ensure it meets international safety and performance standards. Pressure tests, leak tests, and fatigue tests are conducted to validate the integrity and durability of the cylinders. This stringent quality control process not only enhances customer satisfaction but also builds trust in the brand’s reputation.

Sustainability is another critical focus in modern hydraulic rotary cylinder factories. Manufacturers are increasingly adopting eco-friendly practices, from sourcing sustainable materials to implementing energy-efficient processes. Innovations such as using biodegradable hydraulic fluids and recycling scrap materials contribute to reducing the overall carbon footprint of the production process.

Moreover, the staff working in these factories are highly trained professionals. Continuous training and development programs help workers stay abreast of the latest technologies and manufacturing techniques. This commitment to workforce development ensures that organizations maintain a competitive edge in the rapidly evolving industrial market.

In summary, the hydraulic rotary cylinder factory is a cornerstone of modern industrial innovation, combining quality, efficiency, and sustainability. As industries continue to evolve, the demand for reliable hydraulic systems will only increase, and these factories will remain at the forefront, driving advancements that shape the future of industrial applications. By prioritizing technology, quality, and ecological responsibility, hydraulic rotary cylinder factories are setting new standards, ensuring their relevance in an ever-changing market landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025