Aug . 12, 2024 09:32 Back to list

Hydraulic Piston Cylinder System for Enhanced Performance in Industrial Applications and Machinery Solutions

The Importance of Hydraulic Piston Cylinders in Modern Engineering

Hydraulic piston cylinders are essential components in the realm of hydraulic systems, playing a pivotal role in various applications across multiple industries, including construction, manufacturing, automotive, and aerospace. Their ability to convert hydraulic energy into mechanical force makes them indispensable for the operation of heavy machinery and equipment.

Understanding Hydraulic Piston Cylinders

At its core, a hydraulic piston cylinder is a mechanical device that utilizes the principles of hydraulics to produce linear motion. It consists of a cylindrical barrel, within which a piston moves. When hydraulic fluid is injected into the cylinder, it creates pressure that drives the piston forward or backwards, depending on the fluid's direction. The force generated by this movement can be harnessed to lift heavy loads, actuate machinery, or perform a wide range of mechanical tasks.

The basic operation of a hydraulic piston cylinder relies on Pascal’s principle, which states that a change in pressure applied to an enclosed fluid is transmitted undiminished throughout the fluid. This principle allows hydraulic systems to generate large forces with relatively small inputs, making them particularly efficient.

Applications of Hydraulic Piston Cylinders

1. Construction Machinery Hydraulic piston cylinders are fundamental in equipment like excavators, bulldozers, and forklifts. They enable these machines to perform heavy lifting, digging, and moving tasks effectively. For instance, an excavator's boom is powered by hydraulic cylinders that can extend and retract to manipulate attachments like buckets.

2. Manufacturing In factories, hydraulic pistons are used in presses and assembly machines. They can apply significant force necessary for shaping materials or assembling components. For example, in metal forming processes, hydraulic presses use cylinders to press steel into desired shapes.

3. Automotive Industry The automotive sector makes extensive use of hydraulic piston cylinders in systems such as brakes and power steering. Hydraulic brakes use the force of fluid to amplify the force exerted by the driver's foot, providing effective braking power.

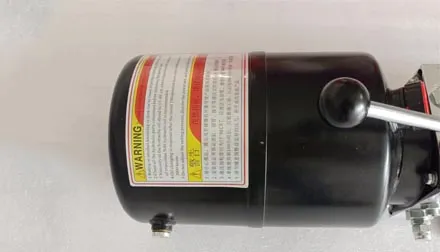

hydraulic piston cylinder product

4. Aerospace In aircraft, hydraulic systems control landing gear, flaps, and brakes. The reliable operation of hydraulic piston cylinders in these systems is critical for ensuring safety and performance during flight.

Advantages of Hydraulic Piston Cylinders

One of the major advantages of hydraulic piston cylinders is their ability to produce high forces with compact and lightweight designs. This is particularly important in applications where space and weight are critical, such as in aerospace and automotive engineering. Furthermore, hydraulic systems can be easily controlled, offering precise movement and force regulation.

Another important benefit is the longevity and durability of hydraulic systems. Piston cylinders are designed to withstand high pressures and harsh conditions, making them suitable for outdoor and industrial settings. With proper maintenance, they can operate efficiently for many years, reducing the need for frequent replacements.

Challenges and Considerations

Despite their benefits, hydraulic piston cylinders also come with challenges. One notable concern is the potential for fluid leaks, which can lead to decreased efficiency and environmental issues. Regular inspections and maintenance are essential to prevent such problems. Additionally, hydraulic systems require appropriate fluids and components to function correctly, making material selection crucial during the design process.

Conclusion

In summary, hydraulic piston cylinders are vital to modern engineering, significantly impacting various sectors by enabling powerful and efficient operations. As industries continue to evolve, the design and application of these hydraulic systems will undoubtedly advance, further enhancing their effectiveness and efficiency. Understanding their function, applications, and benefits can aid engineers and technicians in harnessing the full power of hydraulic technology in their respective fields.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025