Aug . 14, 2024 06:55 Back to list

Hydraulic Manufacturer Specializing in Rotary Cylinder Solutions for Efficient Industrial Applications

The Role and Importance of Rotary Cylinder Hydraulic Manufacturers

In the modern industrial landscape, hydraulic systems have become fundamental to the operation of various machinery. Among these, rotary cylinders stand out for their versatility and effectiveness in converting hydraulic energy into rotational motion. The manufacturers of rotary cylinder hydraulics play a pivotal role in this sector, providing the essential components that drive machinery across diverse applications.

Understanding Rotary Cylinder Hydraulics

Rotary cylinder hydraulics utilize pressurized fluid to generate torque and rotary motion. They are commonly used in applications such as construction, manufacturing, aerospace, and automotive industries. These systems are favored for their ability to deliver high levels of force and precise control in motion. The heart of these systems is the rotary cylinder itself, which can be designed for different specifications based on the requirements of the application.

Key Features of Rotary Cylinders

Rotary cylinders offer several key advantages. Their compact design allows for efficient space utilization in various machines. They also provide high power density, meaning they can produce significant torque relative to their size. Additionally, rotary cylinders are known for their smooth operation and ability to maintain consistent performance, which is crucial for tasks that require precision. Furthermore, advancements in technology have led to the development of hydraulic cylinders with integrated sensors that allow for real-time monitoring and feedback, enhancing their operational efficiency.

The Manufacturing Process

Rotary cylinder hydraulic manufacturers employ a range of technologies and methodologies to produce high-quality products. The process typically begins with designing the cylinder based on customer specifications, which may include size, pressure rating, and operational requirements. Advanced Computer-Aided Design (CAD) software is often used to simulate performance before any physical components are produced.

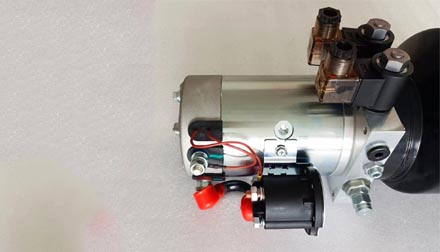

rotary cylinder hydraulic manufacturer

Once the design is finalized, manufacturers utilize precision machining techniques to fabricate the cylinders. This often involves turning, milling, and grinding operations that ensure each component meets exact tolerances. The quality of materials used is also critical, with manufacturers opting for durable alloys that can withstand high pressures and extreme environments.

After machining, the components undergo rigorous testing to ensure they meet safety and performance standards. This may involve pressure testing, leakage tests, and simulations of real-world operating conditions. Only after passing these checks are the rotary cylinders assembled and prepared for distribution.

The Market and Future Trends

The market for hydraulic rotary cylinders is growing steadily, driven by the increasing demand for automation and mechanization in various sectors. As industries strive for greater efficiency and productivity, the need for reliable hydraulic solutions is more pronounced than ever. Manufacturers are investing in research and development to create innovative products that address emerging challenges, such as energy efficiency and eco-friendliness.

Additionally, the integration of smart technology into hydraulic systems is becoming more prevalent. Manufacturers are exploring ways to incorporate IoT capabilities into rotary cylinders, allowing for predictive maintenance and enhancing operational insights. This trend points to a future where hydraulic systems are not only powerful but also intelligent and self-regulating.

Conclusion

Rotary cylinder hydraulic manufacturers are essential players in the industrial machinery ecosystem. Their contributions enable a wide array of applications, from heavy machinery to precise manufacturing tasks. As technology continues to evolve, these manufacturers are poised to meet the growing demands of various industries, driving innovation and offering solutions that enhance productivity and efficiency. The commitment to quality, precision, and continuous improvement will undoubtedly shape the future of rotary cylinder hydraulics, ensuring their pivotal role for years to come.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025