Sep . 17, 2024 04:08 Back to list

High-Quality Hydraulic Locking Cylinder Manufacturer | Reliable Solutions

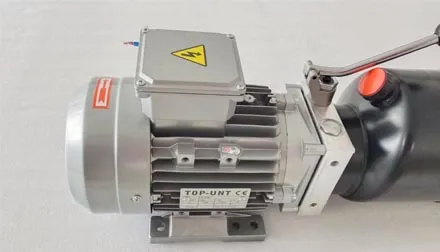

Hydraulic Locking Cylinder Factories An Overview

Hydraulic locking cylinders play a crucial role in various industrial applications, providing a reliable and safe mechanism for securing loads and controlling movements. These specialized devices are integral to systems relying on hydraulic power, offering increased safety and efficiency in operations. As the demand for hydraulic locking cylinders continues to grow across various sectors, the factories producing these components are becoming increasingly important.

Hydraulic locking cylinders operate by using hydraulic pressure to lock the cylinder in place, preventing unintended movement. This feature is critical in heavy machinery and equipment such as cranes, excavators, and industrial automation systems. The locking mechanism ensures that when the system is powered down or in maintenance mode, it remains securely locked, thus protecting personnel and equipment from potential hazards.

Factories producing hydraulic locking cylinders are equipped with advanced technology and skilled labor to meet the demands of this niche market. The manufacturing process typically involves several key stages, including design, material selection, machining, assembly, and quality assurance. Designers utilize computer-aided design (CAD) software to create precise models that meet specific application requirements, ensuring optimal performance and durability.

hydraulic locking cylinder factories

Material selection is vital, as hydraulic locking cylinders must withstand high pressures and extreme operating conditions. Common materials include high-strength steel and aluminum alloys, which provide the necessary tensile strength while maintaining a reasonable weight. These materials are often subjected to stringent testing to ensure they meet or exceed industry standards for safety and performance.

Once the components are fabricated, they undergo a meticulous assembly process. Skilled workers ensure that each part fits perfectly, minimizing the risk of failure during operation. Quality control is paramount; factories implement rigorous testing protocols to verify the performance and reliability of hydraulic locking cylinders. This may include pressure testing, functional testing, and inspection for dimensional accuracy.

As industries evolve and technology advances, hydraulic locking cylinder factories are also adapting to meet new challenges. The integration of automation and robotics in manufacturing processes has improved efficiency and precision, allowing for the production of complex designs that were previously difficult to achieve. Moreover, environmentally friendly practices are increasingly being adopted, with factories seeking sustainable materials and methods to reduce their carbon footprint.

In conclusion, hydraulic locking cylinder factories are at the heart of a critical industry that supports a wide range of applications. Their commitment to quality, innovation, and safety ensures that businesses can rely on these essential components for their operations. As the demand for efficiency and safety continues to rise in various sectors, the importance of hydraulic locking cylinder manufacturers will only increase, driving further advancements in technology and production methods.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025