Jul . 21, 2024 02:48 Back to list

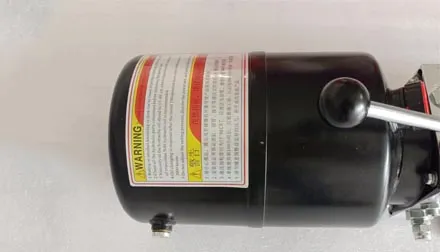

Hydraulic Hand Pump and Cylinder Manufacturing Solutions for Efficient Fluid Power Applications

The Importance of Hydraulic Hand Pumps and Cylinders A Look into the Factory Operations

Hydraulic hand pumps and cylinders play a crucial role in various industrial applications, providing efficient and powerful solutions for lifting and movement

. In a factory that specializes in the manufacturing of these hydraulic components, precision engineering, quality control, and innovation are at the forefront of operations.At its core, a hydraulic hand pump converts human mechanical energy into hydraulic energy, using a liquid to transmit force. This mechanism allows users to lift heavy loads with minimal effort, which is essential in construction, manufacturing, and automotive industries—among others. Hydraulic cylinders, on the other hand, are responsible for converting this hydraulic energy back into linear motion. Together, these components create a reliable system capable of performing tasks that would otherwise be impossible with manual labor alone.

The production process of hydraulic hand pumps and cylinders begins with the selection of high-quality materials, often including steel or aluminum alloys that offer durability and resistance to corrosion. The factory environment is designed for efficiency, where raw materials are meticulously cut, shaped, and finished using advanced CNC (Computer Numerical Control) machines. This technology allows for precise dimensions and high tolerances, which are essential for the proper functioning of hydraulic systems.

Quality control is paramount in the manufacturing of hydraulic components. As these products are often employed in critical applications, any failure could result in significant safety hazards or costly downtime. A dedicated quality assurance team conducts rigorous testing throughout the production process. This includes pressure testing the pumps and cylinders to ensure they can withstand the operational demands they will face in the field. Only components that meet the strict industry standards are permitted to move on to assembly.

hydraulic hand pump and cylinder factory

Once the individual parts are fabricated, they are assembled into the final hydraulic hand pumps and cylinders. This stage of the manufacturing process requires skilled technicians who understand the nuances of hydraulic systems. Each unit is carefully assembled with seals, valves, and other mechanisms that enhance their functionality and reliability. Attention to detail during this phase is critical, as it directly impacts the performance and longevity of the product.

Innovation is a driving force within the factory, as engineers continually seek to improve the design and efficiency of hydraulic systems. Research and development teams work on integrating new technologies, such as lightweight materials or smart sensors, that can provide real-time data on system performance. This commitment to innovation ensures that the products not only meet current industry standards but also anticipate future demands.

Additionally, environmental considerations are becoming increasingly important in the production of hydraulic pumps and cylinders. Factories are adopting sustainable practices, such as recycling waste materials and reducing energy consumption. By utilizing eco-friendly materials and processes, manufacturers can contribute to the preservation of the environment while still delivering high-performance hydraulic solutions.

In conclusion, the factory dedicated to the production of hydraulic hand pumps and cylinders is a hub of precision engineering, quality assurance, and innovation. These components are vital to the operations of many industries, and their reliable performance is a testament to the skilled craftsmanship and technological advancements involved in their manufacture. As the demand for hydraulic solutions continues to grow, so too will the efforts of these factories to meet the evolving needs of their customers while prioritizing safety, efficiency, and sustainability.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025