Aug . 16, 2024 09:55 Back to list

Hydraulic Cylinder Manufacturing for Jet Band Saws in Quality Precision Factories

The Role of Hydraulic Cylinders in Jet Band Saws A Closer Look at Factory Innovations

In the world of industrial manufacturing, the importance of precision and efficiency cannot be overstated. One piece of equipment that exemplifies these qualities is the Jet band saw, a machine designed for cutting a variety of materials with exceptional accuracy. At the heart of this sophisticated piece of machinery lies the hydraulic cylinder, a critical component that significantly enhances the capabilities of the band saw.

Hydraulic cylinders are devices that convert fluid power into mechanical energy. They function by utilizing pressurized hydraulic fluid to create motion, providing the force necessary to operate machinery effectively. In the context of Jet band saws, hydraulic cylinders play a vital role in controlling the cutting arm's movement, allowing for smooth and precise cuts across diverse materials, including wood, metal, and plastics.

The factory where Jet band saws are manufactured employs cutting-edge technology to produce hydraulic cylinders that meet the demanding standards of modern woodworking and metalworking applications. Precision engineering in the fabrication of these cylinders is crucial, as even minor discrepancies can lead to significant issues in performance and safety. Advanced machining processes and quality control measures ensure that every hydraulic cylinder is crafted to perfection, providing the reliability and durability that industrial users expect.

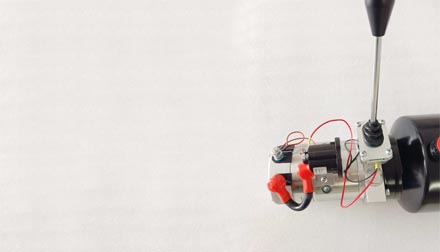

jet band saw hydraulic cylinder factory

One of the key advantages of incorporating hydraulic cylinders into Jet band saws is the ability to maintain constant pressure throughout the cutting process. This feature helps to improve cutting efficiency and extend the lifespan of the saw blades. By providing consistent force, the hydraulic system reduces the chances of blade bind-up, which can not only damage the blade but also compromise the quality of the cut. Moreover, the adaptability of hydraulic systems allows operators to fine-tune the pressure settings, ensuring that the saw is optimized for the specific material being cut.

The functionality of hydraulic cylinders in Jet band saws is not merely about power; it also enhances safety. The controlled operation of the cutting blade minimizes the risk of accidents that can occur with less sophisticated machinery. The design of hydraulic systems allows for smoother starts and stops, reducing the risk of kickback and other dangerous situations that can arise during operation. This focus on safety is paramount in industrial settings, where the stakes are high, and the potential for injury must be mitigated.

Innovation within the factory also extends beyond the manufacturing of the hydraulic cylinders themselves. Continuous research and development efforts are aimed at improving the efficiency and performance of Jet band saws. With the integration of smart technology, operators can monitor hydraulic performance in real-time and make adjustments as needed. This not only enhances the operational capabilities of the saw but also contributes to predictive maintenance, helping to prevent unexpected breakdowns and prolonging the life of the equipment.

In conclusion, the hydraulic cylinders manufactured for Jet band saws are a testament to the advancements in engineering and design within the industrial sector. Their role in enhancing the precision, safety, and efficiency of band saws cannot be overstated. As factories continue to innovate and improve their production processes, the future of cutting technology looks promising, with hydraulic systems at the forefront of this evolution. The combination of powerful performance and refined engineering makes Jet band saws a vital tool for industries reliant on high-quality cuts and reliable machinery.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025