Aug . 16, 2024 23:00 Back to list

Hydraulic Cylinder Factory Specializing in Filter Press Solutions and Manufacturing

The Importance of Filter Press Hydraulic Cylinder Manufacturing

In various industrial processes, the efficiency and reliability of machinery play a crucial role in determining productivity and operational costs. One essential component that significantly impacts these factors is the hydraulic cylinder, particularly those used in filter presses. This article will explore the manufacturing aspects of hydraulic cylinders for filter presses, their applications, and the importance of quality control in this specialized field.

Understanding Filter Presses and Hydraulic Cylinders

Filter presses are widely used in many industries, including mining, chemicals, food processing, and wastewater treatment. They function by applying pressure to filter slurry through membranes or plates, separating solids from liquids effectively. The hydraulic cylinder is a key component that provides the necessary force to compress the filter plates together, ensuring efficient filtration.

Hydraulic cylinders are a type of actuator that converts hydraulic energy into mechanical energy. They work on the principle of Pascal's law, where pressure applied to a confined fluid results in an equal pressure change throughout the fluid. In the context of a filter press, hydraulic cylinders are responsible for moving the plates closer together to create a seal and facilitate the filtration process.

Manufacturing of Hydraulic Cylinders

The manufacturing of hydraulic cylinders for filter presses involves several critical steps, each defined by its own technical requirements and quality standards. The process typically begins with the selection of high-grade materials that can withstand high pressures and corrosive environments. This includes steel or aluminum alloys that provide strength and durability.

After material selection, the manufacturing process involves precision machining. Each cylinder must be precisely manufactured to ensure that it operates smoothly and efficiently. Tolerances in machining are crucial; even a slight deviation can lead to performance issues or failure in the field. CNC (Computer Numerical Control) machines are often employed to achieve the required precision.

Welding and assembly are the next steps, where various components of the hydraulic cylinder, such as the rod, barrel, and end caps, are joined together. This process requires skilled labor and should comply with specific industry standards to ensure safety and reliability.

filter press hydraulic cylinder factory

Quality Control and Testing

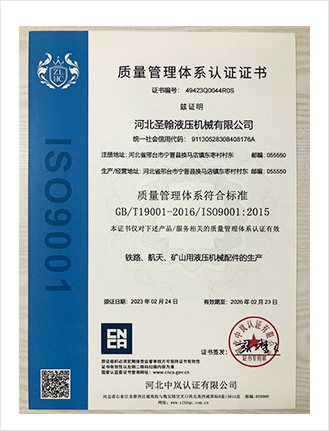

In the manufacturing of hydraulic cylinders, quality control is non-negotiable. It ensures that the final product meets safety and performance standards. Manufacturers typically implement rigorous testing protocols, including pressure testing and hydraulic fluid testing, to verify that each cylinder can withstand operational demands without leaks or failures.

In addition to functional testing, the surface finish of the cylinders is also assessed. A proper finish prevents corrosion and extends the life of the components. The implementation of meticulous inspections throughout the manufacturing process is vital to maintain high standards of quality and reliability.

The Role of Suppliers and Innovation

As industries evolve, the demand for more efficient hydraulic systems increases. Hydraulic cylinder manufacturers must stay ahead in terms of technology and innovation. This includes integrating advanced materials, incorporating automation in manufacturing processes, and adopting new designs that improve performance and reduce costs.

Collaboration with suppliers is also essential. By sourcing high-quality components and materials, manufacturers can enhance the reliability and efficiency of their products.

Conclusion

The manufacturing of hydraulic cylinders for filter presses is a complex and demanding process that requires precision, quality control, and innovation. As industries continue to shift towards more sustainable and efficient practices, the role of competent hydraulic cylinder manufacturers will only grow in significance. By investing in quality manufacturing and fostering innovation, these manufacturers can contribute to the advancement of filtration technology, ultimately benefiting industries that rely on these critical systems for their operations.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025