Aug . 15, 2024 12:28 Back to list

Hydraulic Cylinder Applications and Innovations in China for Tailplate Mechanisms and Machinery

Understanding the Role of Tailplate Hydraulic Cylinders in Modern Machinery

Hydraulic cylinders are crucial components in many industrial and construction applications, providing the force needed to accomplish various tasks. Among the diverse types of hydraulic cylinders, the tailplate hydraulic cylinder plays a vital role in ensuring the efficient operation of machinery. This article explores the characteristics, applications, advantages, and maintenance considerations related to tailplate hydraulic cylinders, particularly in the context of Chinese manufacturing.

Tailplate hydraulic cylinders are specialized devices that utilize hydraulic pressure to generate linear motion. Typically constructed from high-strength materials, these cylinders are designed to withstand extreme pressures while providing reliable performance. The tailplate design enhances the stability and durability of the cylinder, making it an ideal choice for heavy-duty applications such as those found in construction, mining, and manufacturing industries.

Understanding the Role of Tailplate Hydraulic Cylinders in Modern Machinery

In addition to construction equipment, tailplate hydraulic cylinders are also used in various manufacturing processes. For example, they are vital in stamping presses, injection molding machines, and conveyor systems. In these contexts, the cylinders provide the necessary force to mold or shape materials, as well as move products along production lines. This versatility makes them an integral part of manufacturing processes that require precision and efficiency.

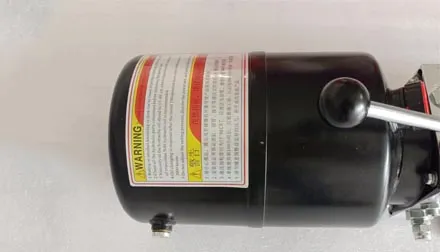

china tailplate hydraulic cylinder

One of the significant advantages of tailplate hydraulic cylinders is their efficiency. Compared to other mechanisms, hydraulic systems can generate high levels of force with relatively small components. This efficiency translates into a compact design, making it easier to integrate hydraulic cylinders into existing machinery without requiring significant modifications. Additionally, the quick response times of hydraulic systems contribute to increased productivity, particularly in fast-paced environments.

Moreover, tailplate hydraulic cylinders offer excellent control over the motion of machinery. Operators can easily regulate the speed and force applied, allowing for precise movements that can improve the quality of work. This level of control is particularly beneficial in applications where delicate handling of materials is crucial, such as in woodworking or metalworking.

However, like any mechanical component, tailplate hydraulic cylinders require regular maintenance to ensure optimal performance. Routine inspections for signs of wear, leaks, or damage are essential to prevent unexpected failures. Operators should also monitor fluid levels and ensure that the hydraulic fluid is clean and free of contaminants. Proper maintenance not only extends the life of the cylinders but also enhances safety during operations.

In conclusion, tailplate hydraulic cylinders are indispensable components in the realm of modern machinery. Their robust design, efficient operation, and capacity for high force generation make them integral in various applications across construction and manufacturing industries. As the demand for advanced machinery continues to grow, the role of hydraulic cylinders, particularly the tailplate variety, will remain critical in ensuring operational effectiveness and safety. By investing in quality hydraulic components and adhering to maintenance protocols, industries can maximize productivity and maintain the longevity of their equipment.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025