Nov . 24, 2024 21:34 Back to list

Top-Notch Hydraulic Cylinder Solutions for Reliable Spring Performance and Durability

High-Quality Spring Hydraulic Cylinder Revolutionizing Fluid Power Technology

In the realm of hydraulic systems, the quality and efficiency of components play a critical role in determining overall performance. Among these components, the spring hydraulic cylinder stands out as a vital feat of engineering that combines power and precision. This article delves into the features and benefits of high-quality spring hydraulic cylinders, exploring their applications and significance in various industries.

High-Quality Spring Hydraulic Cylinder Revolutionizing Fluid Power Technology

One of the hallmarks of high-quality spring hydraulic cylinders is their robust construction. These cylinders are typically made from high-grade materials, such as alloy steels and corrosion-resistant coatings, allowing them to withstand harsh environments and heavy workloads. Manufacturers often employ advanced manufacturing techniques to ensure precision in every component, contributing to a longer lifespan and reduced maintenance requirements. This high level of quality control is essential in sectors such as construction, agriculture, and aerospace, where reliability is non-negotiable.

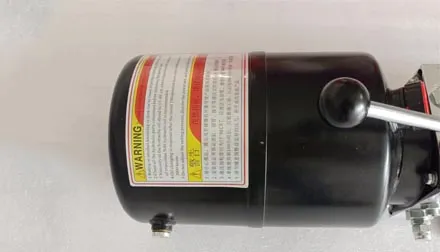

high quality spring hydraulic cylinder

Moreover, the design of spring hydraulic cylinders often incorporates advanced sealing technologies, preventing fluid leaks and reducing the risk of contamination. This aspect is critical for maintaining system integrity and ensuring that hydraulic fluid remains at optimal levels. With fewer leaks and breakdowns, businesses can enjoy increased productivity and lower operational costs, making high-quality spring hydraulic cylinders a smart investment.

Another significant advantage of these cylinders is their versatility. They can be tailored for a wide range of applications, from compact designs suitable for tight installations to larger units capable of handling heavy loads. This adaptability makes them ideal for various industries, including automotive, manufacturing, and robotics. For instance, in automotive assembly lines, spring hydraulic cylinders are used to automate processes, enhance precision, and improve safety standards.

Additionally, environmental considerations have led to innovations in spring hydraulic cylinder technology. Many manufacturers are now designing cylinders that use biodegradable hydraulic fluids and energy-efficient operating mechanisms. This shift not only aligns with global sustainability goals but also responds to rising regulatory pressures. As industries become more conscious of their environmental footprint, high-quality spring hydraulic cylinders offer a way to optimize performance sustainably.

In conclusion, high-quality spring hydraulic cylinders represent a cornerstone of modern hydraulic technology. Their superior construction, efficient design, and adaptability to varied applications make them essential in numerous industries. As businesses continue to look for ways to enhance efficiency and sustainability, investing in these advanced hydraulic components will undoubtedly yield significant returns. Whether for large-scale industrial applications or precision machinery, high-quality spring hydraulic cylinders are poised to revolutionize fluid power technology, driving innovations that shape the future of engineering and manufacturing.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025