Dec . 11, 2024 18:54 Back to list

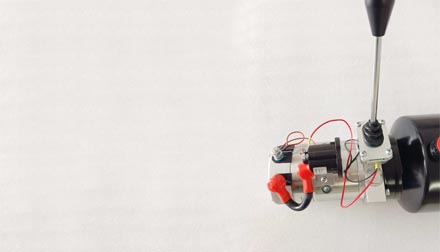

high quality side mount hydraulic cylinder

High-Quality Side Mount Hydraulic Cylinders An Overview

Hydraulic cylinders are essential components in a myriad of machinery and equipment, providing the necessary force to accomplish various tasks. Among the different types of hydraulic cylinders, side mount hydraulic cylinders stand out due to their unique design and versatility. This article delves into the characteristics and benefits of high-quality side mount hydraulic cylinders, their applications, and important considerations for selecting the right one.

What is a Side Mount Hydraulic Cylinder?

A side mount hydraulic cylinder is a type of hydraulic actuator mounted on the side of a machine or structure. Unlike traditional cylinders that may be mounted in line with the load, side mount cylinders are designed to offer lateral force application. This design permits a more compact installation in situations where space is a constraint or when the machinery layout necessitates side mounting.

Key Features of High-Quality Side Mount Hydraulic Cylinders

1. Durability and Strength High-quality side mount hydraulic cylinders are constructed from robust materials such as alloy steel or stainless steel, ensuring they can withstand high pressures and challenging working environments. The cylinder body is often designed to resist corrosion, wear, and fatigue, extending the lifespan of the equipment.

2. Precision Engineering Quality side mount hydraulic cylinders benefit from precise engineering and manufacturing processes. Tolerances are tightly controlled to ensure optimal performance, with attention given to sealing mechanisms to prevent leaks and maintain efficiency.

3. Versatile Mounting Options High-quality models typically provide a range of mounting configurations, allowing them to be integrated easily into various machinery and applications. Whether for industrial machinery, construction equipment, or material handling systems, these cylinders can be tailored to fit specific requirements.

4. Smooth Operation A well-designed hydraulic cylinder operates smoothly and efficiently. High-quality side mount hydraulic cylinders are equipped with advanced sealing technologies that facilitate low friction and allow for rapid responsiveness during operation.

5. Variety of Sizes and Stroke Lengths High-quality manufacturers offer a broad spectrum of sizes and stroke lengths, catering to diverse operational needs. This variability ensures that businesses can find the ideal cylinder that meets their specific horsepower requirements without compromising performance.

high quality side mount hydraulic cylinder

Applications of Side Mount Hydraulic Cylinders

High-quality side mount hydraulic cylinders are used across a wide array of industries, including but not limited to

- Construction In excavators, bulldozers, and other heavy machinery, side mount cylinders can be used to control booms, arms, or other actuating components. - Manufacturing In production lines, these cylinders facilitate the operation of presses, lifts, and conveyor systems, helping automate processes and improve productivity. - Agriculture Equipment such as tractors and harvesters utilize side mount cylinders for steering mechanisms and other operational functions. - Material Handling In warehouses and distribution centers, side mount hydraulic cylinders play a key role in operating conveyor belts, lifts, and pallet trucks. Selecting the Right Side Mount Hydraulic Cylinder

When choosing a side mount hydraulic cylinder, several factors should be taken into consideration to ensure optimal performance

1. Pressure Ratings Evaluate the operational pressure requirements of your application and ensure that the cylinder can handle those pressures.

2. Load Capacity Consider the weight and force that the cylinder will need to move. It's essential to select a model that can accommodate these specifications without risk of failure.

3. Environment Assess the working environment for factors like temperature extremes, exposure to corrosive substances, and potential physical impacts. This evaluation will guide the selection of materials and protective coatings.

4. Seal Type The type of sealing system affects the efficiency and maintenance of the cylinder. High-quality seals that minimize leakage and wear can drastically enhance reliability.

5. Customization Options Look for manufacturers that offer customization services, allowing you to tailor the cylinder to exact specifications to match the unique demands of your application.

In conclusion, high-quality side mount hydraulic cylinders are pivotal in enhancing the functionality, efficiency, and safety of various equipment across different industries. Selecting the right cylinder tailored to specific needs is crucial for optimizing performance and ensuring long-term operational success. Whether for construction, manufacturing, or material handling, investing in reliable hydraulic solutions is essential for any business seeking to improve its capabilities and output.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025