Nov . 14, 2024 06:13 Back to list

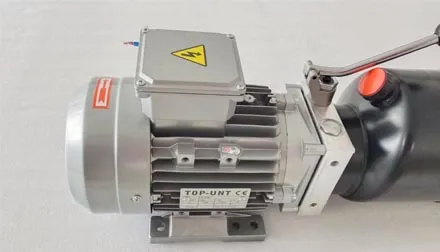

high quality hydraulic wheel cylinder

High-Quality Hydraulic Wheel Cylinders Elevating Performance and Reliability in Automotive Engineering

Hydraulic wheel cylinders play a crucial role in modern automotive braking systems—ensuring safe and efficient stopping performance in vehicles ranging from passenger cars to heavy-duty trucks. As the demand for enhanced safety and performance in automotive engineering continues to rise, the importance of high-quality hydraulic wheel cylinders cannot be overstated. This article delves into the features, manufacturing processes, and advantages of high-quality hydraulic wheel cylinders that contribute to overall vehicle safety and efficiency.

Understanding Hydraulic Wheel Cylinders

A hydraulic wheel cylinder is a cylindrical device that utilizes hydraulic fluid to create the force necessary for braking. Located within the drum brakes or disc brake assembly, these cylinders convert the pressure generated by the brake pedal into a mechanical force that pushes the brake shoes or pads against the braking surface. The efficient operation of hydraulic wheel cylinders is essential for providing responsive braking performance, which is critical for vehicle safety.

Manufacturing Quality The Cornerstone of Performance

The performance of hydraulic wheel cylinders is significantly influenced by the quality of materials and manufacturing processes employed. High-quality hydraulic wheel cylinders are typically made from corrosion-resistant alloys and high-strength materials that can withstand the pressures generated during braking. Advanced manufacturing techniques such as precision machining, heat treatment, and rigorous quality control measures are critical to ensure that every cylinder meets stringent industry standards.

Precision machining is particularly important as it ensures the internal components of the cylinder, including bore and piston surfaces, are smooth and free from defects. This smoothness reduces friction and wear, allowing for better fluid flow and longevity of the component. Moreover, high-quality seals made from durable materials enhance the cylinder's resistance to hydraulic fluid and environmental contaminants, further prolonging service life.

Performance Benefits

high quality hydraulic wheel cylinder

Investing in high-quality hydraulic wheel cylinders brings numerous benefits that enhance vehicle performance and reliability. One of the most notable advantages is improved braking response. When hydraulic wheel cylinders are manufactured to high precision, they allow for more efficient transfer of force, resulting in quicker response times when the brake pedal is engaged. This is not only vital for daily driving scenarios but also becomes increasingly important in emergency situations where swift braking can mean the difference between safety and disaster.

Additionally, high-quality hydraulic wheel cylinders offer better heat dissipation. The braking process generates considerable heat, which can lead to brake fade if not effectively managed. Utilizing advanced materials and designs helps to dissipate heat more efficiently, maintaining optimal braking performance even under extreme conditions.

The Role of Quality Assurance

Quality assurance is a paramount factor in the production of hydraulic wheel cylinders. Reputable manufacturers implement comprehensive testing procedures to assess each unit's performance before it reaches the market. Tests often include pressure tests, leak tests, and endurance tests to ensure that each cylinder can operate under real-world conditions without failure.

Furthermore, adherence to international standards, such as ISO and SAE specifications, ensures that the hydraulic wheel cylinders produced are reliable, durable, and capable of maintaining performance across varying conditions. This commitment to quality not only enhances safety but also builds customer trust—a vital component in the competitive automotive parts industry.

Conclusion

In conclusion, high-quality hydraulic wheel cylinders are indispensable components in modern automotive braking systems. Their role in ensuring safe, efficient, and responsive braking cannot be overlooked. By prioritizing quality in materials and manufacturing processes, manufacturers can produce hydraulic wheel cylinders that significantly enhance vehicle performance, safety, and reliability. As technology advances and new automotive standards emerge, the importance of investing in high-quality components will continue to grow, ultimately leading to safer roads and a better driving experience for everyone. Whether it’s a personal vehicle or a commercial fleet, the significance of high-quality hydraulic wheel cylinders remains a critical aspect of automotive engineering.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025