Nov . 28, 2024 06:11 Back to list

Durable and Efficient Hydraulic Loader Cylinder for Improved Performance and Reliability

High-Quality Hydraulic Loader Cylinders The Backbone of Efficient Machinery

The modern construction and agricultural sectors are heavily reliant on equipment that enhances productivity, efficiency, and safety. At the heart of many of these machines, particularly loaders, are hydraulic cylinders. These components are crucial for the functionality of loaders used in various applications, from earthmoving to material handling. This article delves into the importance of high-quality hydraulic loader cylinders, outlining their benefits, construction, and maintenance.

Understanding Hydraulic Loaders

Hydraulic loaders are types of heavy machinery designed to move bulk materials. They operate using hydraulic systems that harness fluid pressure to generate force. The hydraulic cylinders are the muscles of this operation, converting hydraulic energy into mechanical energy, enabling the loader to lift, tilt, and maneuver heavy loads effortlessly.

Importance of High-Quality Hydraulic Cylinders

1. Durability High-quality hydraulic cylinders are engineered to withstand the harsh conditions typical in construction and agricultural environments. They are constructed from robust materials that resist wear and tear, corrosion, and high pressures. A well-made cylinder can endure continuous use, reducing the need for frequent replacements and repairs.

2. Performance The efficiency of a loader directly correlates with the quality of its hydraulic cylinders. High-quality cylinders provide consistent and reliable performance, allowing operators to execute tasks smoothly and effectively. This efficiency not only enhances productivity but also minimizes operational costs—something that every business values.

3. Safety Safety is paramount in any machinery operation. Hydraulic cylinders must perform optimally to ensure the safety of operators and personnel nearby. High-grade hydraulic cylinders are designed with safety features, such as advanced seals and robust construction, to prevent leaks and failures that could result in dangerous situations.

4. Precision In applications where precision is crucial, such as in landscaping or demolition, high-quality hydraulic cylinders contribute to better control over the loader’s movements. This precision is essential for tasks that require intricate maneuvering, ensuring that materials are handled safely and accurately.

Construction of Hydraulic Cylinders

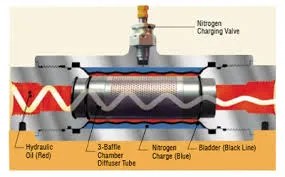

The construction of a hydraulic loader cylinder involves several key components

- Barrel The main structure of the cylinder, which houses the hydraulic fluid

. It is typically made from high-strength steel to withstand various pressures.high quality hydraulic loader cylinder

- Piston This component is responsible for translating the hydraulic pressure into mechanical force. The piston must fit perfectly within the barrel to maintain efficiency and prevent leaks.

- Rod Connected to the piston, the rod extends and retracts, applying force to the loader. The rod's surface must be smooth and strong to endure the friction and impact associated with heavy lifting.

- Seals Quality seals prevent hydraulic fluid from leaking and maintain pressure within the system. They are crucial for the longevity and reliability of the cylinder.

Maintenance of Hydraulic Cylinders

To ensure that hydraulic cylinders perform optimally, regular maintenance is vital. Here are some tips

- Routine Inspections Regularly check for leaks, cracks, or signs of wear. Early detection of these issues can prevent costly repairs and downtimes.

- Fluid Replacement The hydraulic fluid should be replaced periodically to maintain optimal performance. Contaminated fluid can lead to erosion of internal components.

- Seal Checks Inspect seals for wear and tear; they are essential for maintaining pressure and preventing fluid loss.

- Cleanliness Keep hydraulic systems clean to prevent dirt and debris from entering the cylinder, which can cause significant damage.

Conclusion

High-quality hydraulic loader cylinders are an integral component of efficient machinery used in construction and agriculture. Their durability, performance, safety, and precision contribute significantly to the overall effectiveness of loaders. Investing in high-quality cylinders not only enhances productivity but also ensures the safety and reliability of operations. Regular maintenance and attention to these components will maximize their lifespan, providing operators with reliable service for years to come. As industries continue to evolve, the importance of superior hydraulic technology will only grow, cementing the role of high-quality hydraulic loader cylinders in future innovations.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025