Nov . 05, 2024 14:49 Back to list

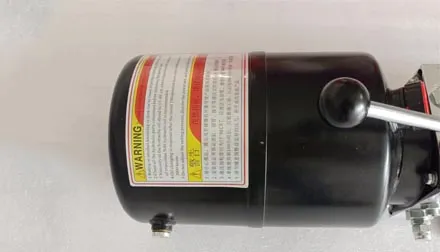

high quality hydraulic cab tilt cylinder

High-Quality Hydraulic Cab Tilt Cylinders Essential Components for Modern Vehicles

In the realm of heavy machinery and commercial vehicles, hydraulic systems play a crucial role in enhancing efficiency and functionality. One of the pivotal components of these systems is the hydraulic cab tilt cylinder. This article delves into the importance of high-quality hydraulic cab tilt cylinders, their functionality, applications, and the factors to consider when choosing them for vehicles.

Functionality and Importance

Hydraulic cab tilt cylinders are designed to facilitate the tilting of a vehicle's cab, providing easy access to the engine and other critical components for maintenance and repairs. This function is essential for heavy trucks, buses, and construction equipment, where regular maintenance is necessary to ensure optimal performance. The ability to tilt the cab allows technicians and operators to perform inspections, repairs, and servicing efficiently, reducing downtime and enhancing productivity.

The operation of the hydraulic cab tilt cylinder is based on hydraulic pressure, which acts on the cylinder to produce a smooth and controlled tilting motion. High-quality hydraulic cylinders ensure reliability and safety, preventing leaks that could lead to dangerous situations or equipment failures. Moreover, with advancements in hydraulic technology, modern cylinders are designed to be more compact, lightweight, and efficient, catering to the increasing demands of the industry.

Applications Across Industries

The applications of hydraulic cab tilt cylinders are vast and varied

. In the trucking industry, these cylinders are used in heavy-duty trucks, allowing the cab to tilt forward for engine access. This is particularly helpful in long-haul trucks where routine maintenance is crucial for driver safety and vehicle longevity.In construction, equipment like excavators and bulldozers utilizes cab tilt systems to provide mechanics with better access to machinery components. Similarly, buses equipped with hydraulic cab tilt cylinders allow for easier maintenance, making it possible to quickly address engine or electrical system issues, thus ensuring that public transport vehicles remain operational and safe for passengers.

high quality hydraulic cab tilt cylinder

Beyond transportation, these cylinders are also found in agricultural machinery, where easy access to complex engine systems is vital for productivity during peak seasons. In essence, the hydraulic cab tilt cylinder is a versatile component that enhances the functionality of various vehicles and machinery.

Choosing the Right Hydraulic Cab Tilt Cylinder

Selecting a high-quality hydraulic cab tilt cylinder involves several considerations. First and foremost is compatibility with the specific vehicle model. Each machine has unique structural and mechanical requirements, thus selecting a cylinder that matches these specifications is crucial.

Moreover, the cylinder's construction materials play a significant role in its durability and performance. High-quality steel and advanced seal technologies can prevent leaks and ensure that the cylinder operates smoothly over time. Additionally, the cylinder should be resistant to corrosion and wear, particularly in applications exposed to rough environments such as construction sites or agricultural fields.

Lastly, it is essential to consider the manufacturer's reputation and warranty offered. Reliable manufacturers will typically provide detailed specifications, testing results, and customer support, ensuring that buyers can make informed decisions.

Conclusion

In conclusion, high-quality hydraulic cab tilt cylinders are indispensable components for a variety of vehicles, providing ease of maintenance and enhancing operational efficiency. Their ability to improve access to engine components minimizes downtime and boosts productivity across industries. When selecting a hydraulic cab tilt cylinder, it is essential to consider compatibility, build quality, and the manufacturer's credentials. Investing in a high-quality hydraulic cab tilt cylinder not only enhances vehicle performance but also ensures safety and longevity in operations. As the demand for efficient and reliable machinery continues to grow, the importance of these hydraulic components cannot be overstated.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025