Nov . 11, 2024 01:36 Back to list

Top-rated hydraulic air cylinders for optimal performance and reliability in various applications

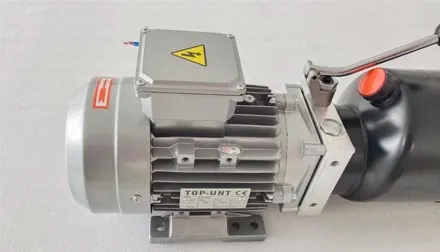

High-Quality Hydraulic Air Cylinder An Essential Component for Modern Machinery

In the realm of industrial automation and manufacturing, hydraulic air cylinders play a pivotal role in the efficiency and effectiveness of various systems. These devices harness the power of hydraulic pressure and pneumatic energy to produce motion and force, making them invaluable in countless applications. Understanding the significance of high-quality hydraulic air cylinders is crucial for businesses aiming to optimize their operations and enhance their machinery's performance.

What is a Hydraulic Air Cylinder?

A hydraulic air cylinder is a device that converts hydraulic energy into linear motion, often utilizing compressed air to assist in its operation. The cylinder consists of a piston housed within a cylindrical barrel, where hydraulic fluid is used to create pressure on one side of the piston. This pressure causes the piston to move, producing the desired mechanical output. When integrated with pneumatic systems, the air cylinder can augment its performance, allowing for smoother operation and greater versatility.

The Importance of Quality

The effectiveness of a hydraulic air cylinder is heavily influenced by the quality of its construction and materials. High-quality cylinders offer numerous advantages, including

1. Durability Quality cylinders are designed to withstand the rigors of demanding industrial environments. They are typically crafted from robust materials like high-strength aluminum or steel, ensuring resistance to wear, corrosion, and fatigue. This longevity reduces the frequency of replacements and maintenance, ultimately lowering operational costs.

2. Precision and Reliability A well-manufactured hydraulic air cylinder delivers consistent performance, critical for applications requiring precision. High-quality designs ensure tight tolerances, minimizing the risk of leaks and malfunctions. This reliability translates to fewer downtimes and enhanced productivity.

3. Enhanced Efficiency High-quality hydraulic air cylinders operate more efficiently than their lower-quality counterparts. They are optimized to minimize energy losses, resulting in reduced operational costs and lower environmental impact. This efficiency is vital in today's competitive landscape, where cost-effectiveness and sustainability are essential.

4. Wide Range of Applications Quality cylinders are versatile, suitable for various applications across different industries, including automotive, aerospace, manufacturing, and construction. Their ability to perform effectively under various conditions makes them an essential component in diverse machinery.

high quality hydraulic air cylinder

Choosing the Right Hydraulic Air Cylinder

When selecting a hydraulic air cylinder, several factors should be considered to ensure optimal performance. These include

- Operating Pressure Understanding the required operating pressure for your application is crucial. Ensure that the selected cylinder can handle the maximum pressure without risking failure. - Stroke Length Choose a cylinder with a stroke length that meets the specific needs of your application. Too short a stroke can limit movement, while an overly long stroke can waste space and resources.

- Mounting Options Consider the mounting configurations available. Different applications require different mounting styles, such as rod-end, clevis, or flange mounting.

- Environmental Conditions Evaluate the environmental conditions in which the cylinder will operate. Factors like temperature, humidity, and exposure to corrosive substances can influence material selection and design.

Maintenance and Care

To maximize the lifespan and performance of hydraulic air cylinders, regular maintenance is essential. Routine inspections should focus on checking for leaks, ensuring seals are intact, and verifying the proper function of pneumatic components. Keeping the hydraulic fluid clean and at the appropriate levels is also vital for preventing wear and tear.

Conclusion

In conclusion, high-quality hydraulic air cylinders are indispensable components in modern machinery, providing reliability, efficiency, and versatility across various industries. Businesses looking to enhance their operational effectiveness must prioritize the selection of high-quality hydraulic air cylinders, considering pressure requirements, stroke length, and environmental factors. By investing in superior components and committing to regular maintenance, companies can ensure the longevity and performance of their machines, driving productivity and success in an increasingly competitive market.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025