Nov . 27, 2024 10:29 Back to list

Detailed Illustration of a Hydraulic Cylinder with High Precision and Realistic Design

The Importance of High-Quality Drawings in Hydraulic Cylinder Design

Hydraulic cylinders are essential components in various industrial applications, providing the power needed for lifting, pushing, and pulling tasks. Their design and functionality depend heavily on precise engineering, and high-quality drawings play a pivotal role in their development. In this article, we will explore the significance of high-quality drawings for hydraulic cylinders, their components, and the overall process of their design and manufacture.

Understanding Hydraulic Cylinders

Before delving into the importance of high-quality drawings, it’s crucial to understand what hydraulic cylinders are. These devices convert hydraulic energy into mechanical energy, using pressurized fluid to create movement. Commonly used in construction equipment, manufacturing machinery, and even automotive applications, hydraulic cylinders consist of several key components the cylinder barrel, piston, rod, end caps, and seals. The efficiency and reliability of these components directly impact the performance of the hydraulic system in which they operate.

The Role of High-Quality Drawings

High-quality technical drawings serve as the blueprint for manufacturing hydraulic cylinders. They provide detailed specifications and dimensions for all components, ensuring that they are fabricated accurately. Here are a few reasons why these drawings are vital

1. Precision and Accuracy The success of hydraulic systems hinges on precision. High-quality drawings allow engineers and manufacturers to share exact specifications that help avoid discrepancies during fabrication. This precision is particularly critical since even a slight variation can lead to leaks or mechanical failure.

2. Communication Drawings are a universal language in engineering. High-quality visuals help teams communicate effectively, allowing engineers, designers, and machinists to work together seamlessly. Clear drawings minimize misunderstandings and facilitate a smoother workflow throughout the development process.

3. Quality Control High-quality drawings also play a crucial role in the quality control process. They serve as a reference point to measure the finished components against to ensure they meet the required standards. This is especially important in industries where safety and efficiency are paramount.

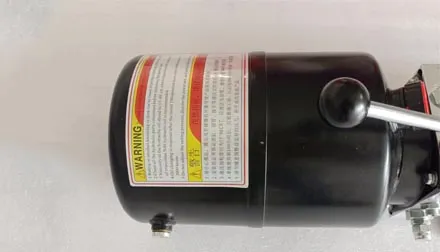

high quality drawing hydraulic cylinder

4. Time and Cost Efficiency Investing time in creating detailed, high-quality drawings ultimately saves both time and resources. By providing clear guidance to manufacturers, the likelihood of errors decreases, reducing the need for costly corrections or re-manufacturing. This efficiency is vital for staying within budget and meeting project deadlines.

Components of High-Quality Drawings

To be effective, high-quality technical drawings must contain several key elements

- Dimensions and Specifications Every important measurement must be clearly labeled. This includes lengths, diameters, tolerances, and angles, which are critical for proper assembly and functionality.

- Material Specifications Indicating the correct materials for each component is essential. Different applications may require varying materials, each with its own properties impacting durability and performance.

- Assembly Instructions Including detailed assembly diagrams or step-by-step instructions can help ensure that hydraulic cylinders are put together correctly. This can also be beneficial for maintenance and repairs in the future.

- Notes and Annotations Providing additional notes, such as safety instructions or specific manufacturing techniques, can further enhance the understanding of the drawing and the intended functionality of the hydraulic cylinder.

Conclusion

High-quality drawings are indispensable in the design and manufacture of hydraulic cylinders. They ensure precision, enhance communication, facilitate quality control, and ultimately contribute to cost and time efficiency in manufacturing processes. As industries continue to evolve and demand more advanced hydraulic systems, the importance of investing in meticulous and high-quality technical drawings will only grow. By prioritizing these aspects in the design of hydraulic cylinders, engineers and manufacturers can ensure the reliability and efficiency of the systems that rely on these critical components.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025